What is Air Leakage?

Air leakage is the unwanted flow of air through the wall of a vessel or sealed container. Pressure variation from the inside of the vessel to the atmosphere outside the vessel cause the air to flow from higher pressure to lower pressure areas. Air leakage generally occurs from the inside out—from inside an object (higher pressure) to outside the object (lower pressure)—but can also happen from the outside in when ambient atmosphere flows into an evacuated (vacuum) vessel.

What is Air Leak Testing?

Air leak testing is an effective method of determining if a product has been manufactured to meet leak-tight specifications. Microscopic holes, failed seals, and countless other defects can cause air leaks that can lead to significant problems. Everything from automotive radiators to medical devices to sprinkler system components requires air leak testing to ensure proper and safe operation.

In general, air leak testing is clean, non-destructive, and highly repeatable. Air leak tests can be performed on any product that requires air-tight or water-tight construction. It is used not only to detect leaks, but also to provide non-subjective data on leakage rates for further analysis. Air leak testing helps OEMs ensure that their products meet the required leak-tight specifications and helps them find and eliminate design and/or manufacturing flaws.

Advantages of Air Leak Testing

Compared to other leak test processes, air leak testing provides significant advantages in three key areas: time/work saving, quality improvement, and cost reduction.

Time Saving/Work Saving

Many air leak testing processes can be fully or partially automated

Most air leak testing equipment is relatively easy to use, with no special training required

Maintenance is generally easy, and requirements are minimal

Quality Improvement

Leak standards can be quantified

Product defect rate can be greatly reduced

Leak measurement data can be used in statistical processing/analysis for future product improvements

Cost Reduction

How to Choose an Air Leak Tester

The most important factor to consider when choosing an air leak testing device is the acceptable leak rate of the tested part or vessel. The largest influence on the acceptable leak rate is the media that must be retained—is it liquid/fluid or gaseous? Air, for example, will pass through a leak path up to 300 times faster than water will travel that same path. Standard non-water (air or gas) leak rates are generally between 1-5 scc/min (standard cubic centimeters per minute), though sometimes as high as 10 scc/min.

The other key factor in selecting an air leak tester is that the device must be capable of supplying at least 100 times greater resolution than the leak rate being measured.

What's the Difference Between Air Leak Testing & Pressure Testing?

Air leak testing is intended to detect and locate leaks in sealed, pressurized part or vessel. A wide variety of air leak detection procedures may be used.

Pressure testing, or proof-pressure testing, is a form of stress testing used to verify that a component can withstand pressures above its intended operating range without incurring permanent damage. Most pressure testing is done via hydrostatic or pneumatic testing.

Air Leak Testing for Medical Devices

Air leak testing is extremely important for medical devices to ensure proper operation and patient health. Many medical devices utilize fluids, gases, or both, thus providing effective barriers for and ensuring the correct passage of these media is critical for the device’s performance and to protect the patient. In general, sample testing is insufficient— of parts and components must be tested.

The most common air leak testing methods for medical devices are pressure decay, vacuum decay, and tracer gas testing . Hydrogen is the most commonly used tracer gas, because it tends to spread quickly to penetrate leaks and vents away faster than most other tracer gases. Special considerations must be made for medical device air leak testing, such as testing that is not destructive or corrosive to tested parts, adjustments for flexible or elastic materials, and proper tracer gas removal for sequential testing.

Performing Automotive Air Leak Testing

There are dozens of components and systems in an automobile that may require air leak testing. Common automotive parts that may require air leak testing include brake lines, exhaust components, engine intake manifolds, radiators, and A/C components, among many others.

A number of air leak detection options may be used, depending on where the leak may be originate. From simple soap-and-water spray testing to advanced vacuum or pressure decay testing systems, these tests can give a better look at the air leak problem by pinpointing the location of the leak and measuring its severity.

How to Leak Test Automotive Fuel Rails

High pressure fuel injection is the key to lower fuel consumption in modern automobiles. An improperly calibrated fuel injection system can lead to poor gas mileage, a fire in the engine compartment, or worse. Most vehicles use high pressure direct injection fuel rails, which may operate at pressures as high as 2,000 bar (roughly 150,000 psi).

Fuel rails need to be pressure tested during production to protect against fuel leakage. Most often, the complete subassembly (fuel rail with fuel injectors) is tested; connections and fittings must be tested, as well, after final assembly. The maximum allowable leak rate, in most cases, is 10-4 scc/s.

The most common fuel rail air leak testing method is actually a tracer gas test using helium under vacuum. The fuel rail subassembly is sealed, then enclosed in a chamber; fuel rail and chamber are evacuated simultaneously. The fuel rail is backfilled with helium, and any leakage of helium into the chamber indicates a leak. Clamshell leak testers may also be used—these devices enclose the individual connectors being tested, then use the same general process of evacuation and helium backfill.

Advantages of tracer gas leak testing include accurate and repeatable measurements and high leak sensitivity to detect very fine leaks.

Air Leak Testing Equipment

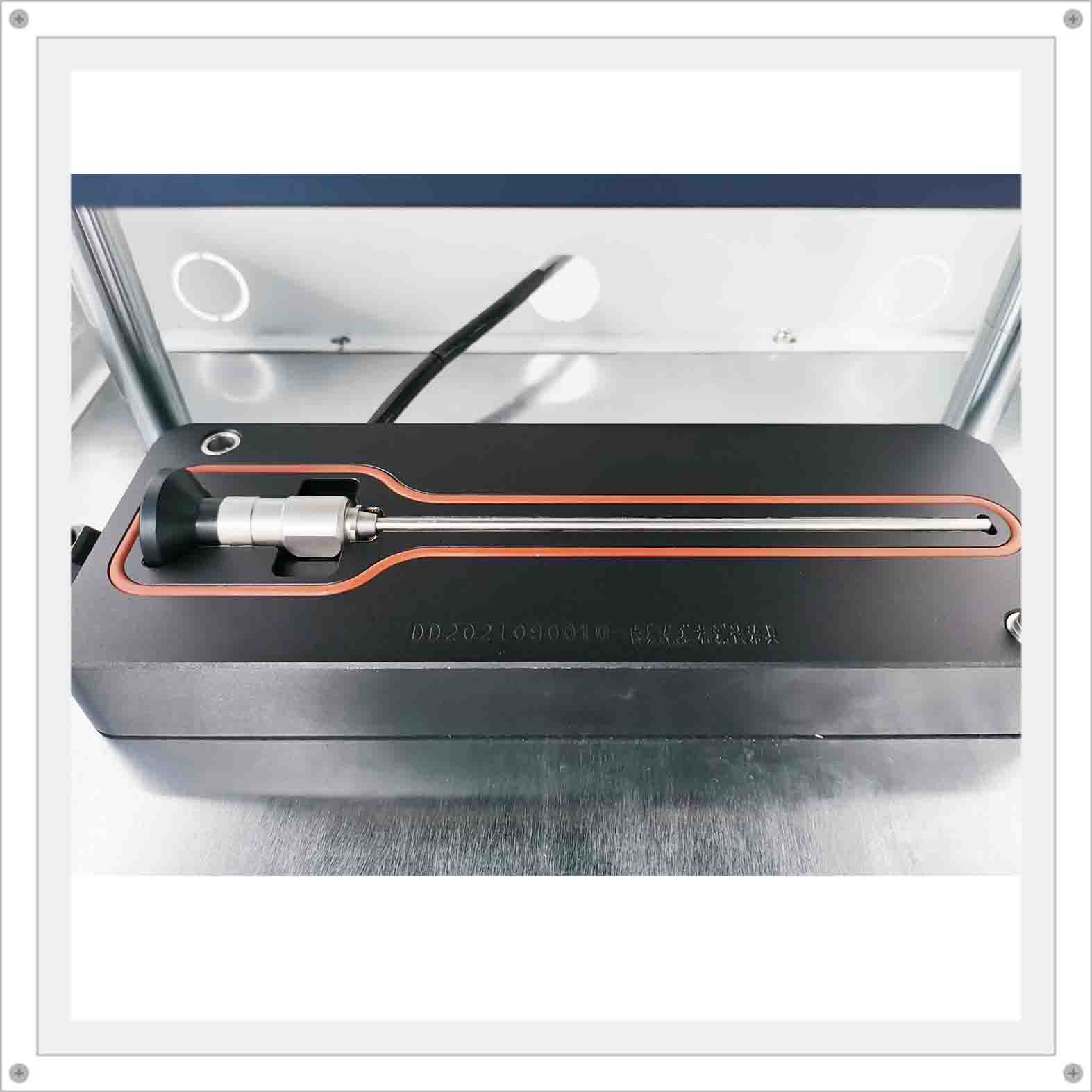

Hirays offers a full line of air leak testing equipment and accessories. We also offer custom-engineered systems made to match your exact testing specifications. Our air leak test systems include:

HC Classic Air Leak Tester

HP Air Leak Tester

HD-28 Ingenuity Air Leak Tester

HL Leader Air Leak Tester

HW True Water Tester

HV110 Battery Pack Air Leak Tester

If you need a leak tester machine,we have everything you are looking for.To learn more about our products,contract us for more information,thanks so much!