New energy vehicles' die casting leak testing

- Model: New energy vehicles' die casting leak testing

- Category: new energy vehicles

- details:

Automotive die-casting refers to metal parts used in automobiles, including engines, transmissions, rear axle housings and other parts. Poor performance of die castings, such as poor sealing performance, is easy to shorten the service life of accessories, thus affecting the use of vehicles.

Therefore, the leak test of die castings is one of the necessary procedures for manufacturers.

Today we are sharing a case about the air leak test of die castings for new energy vehicles.

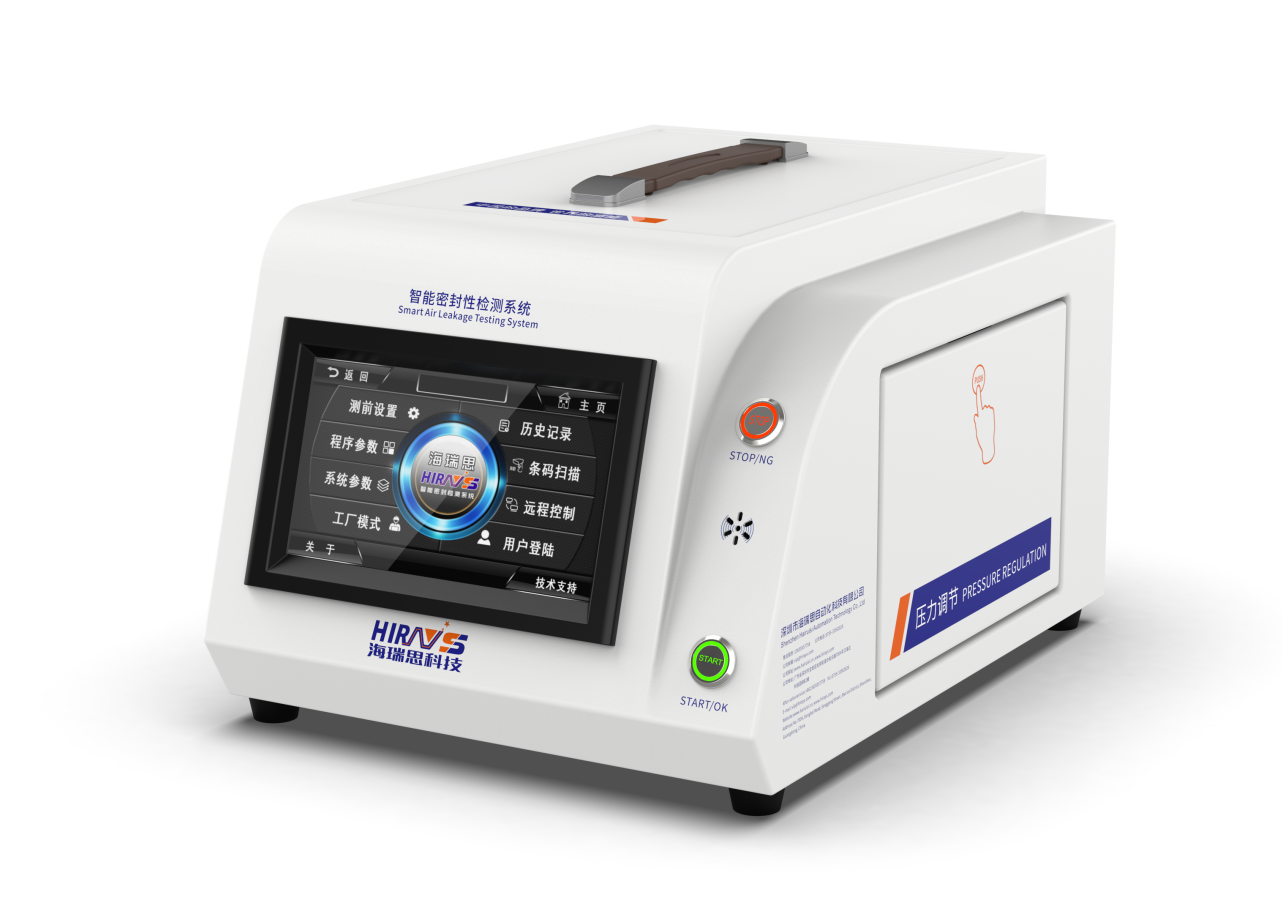

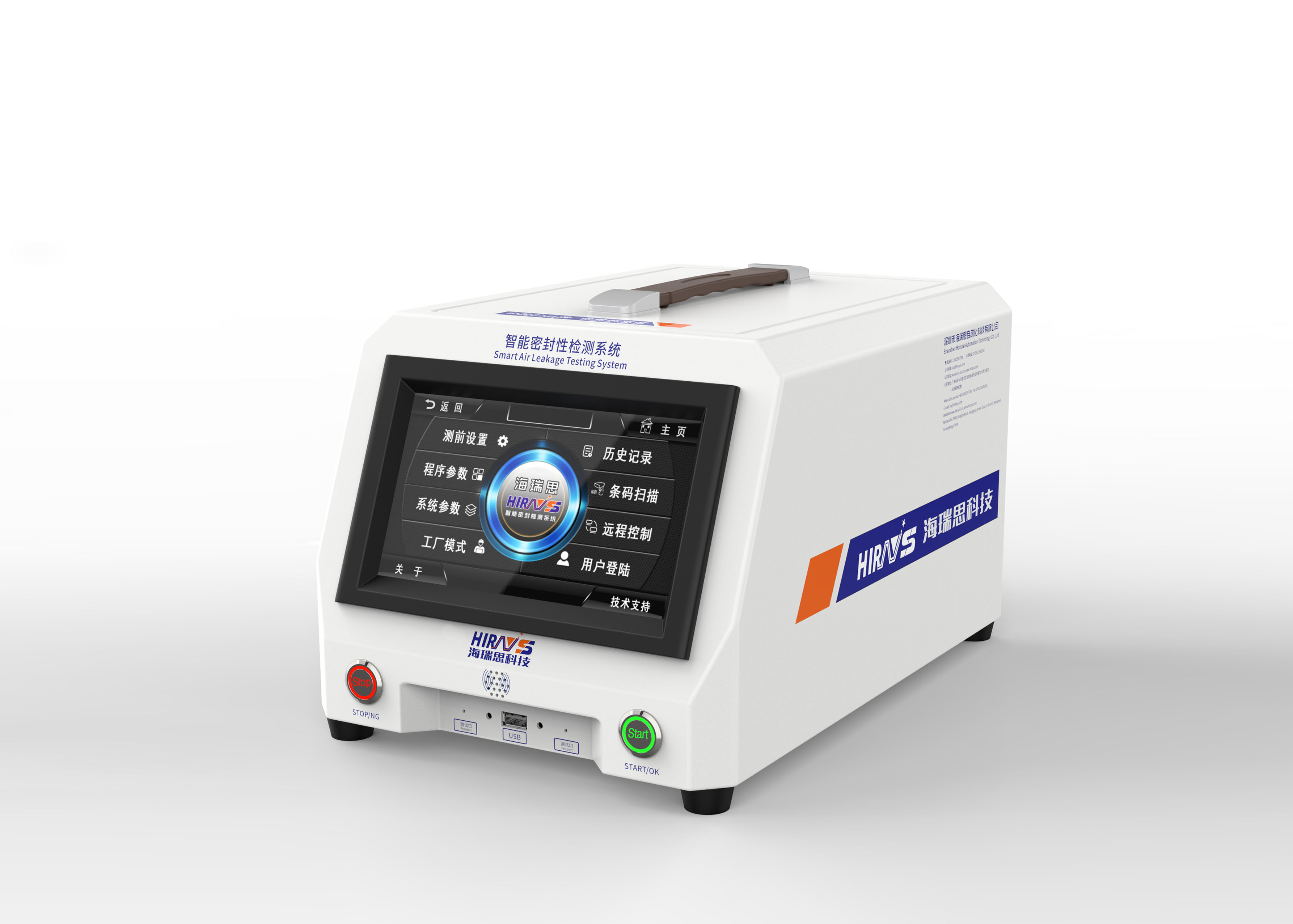

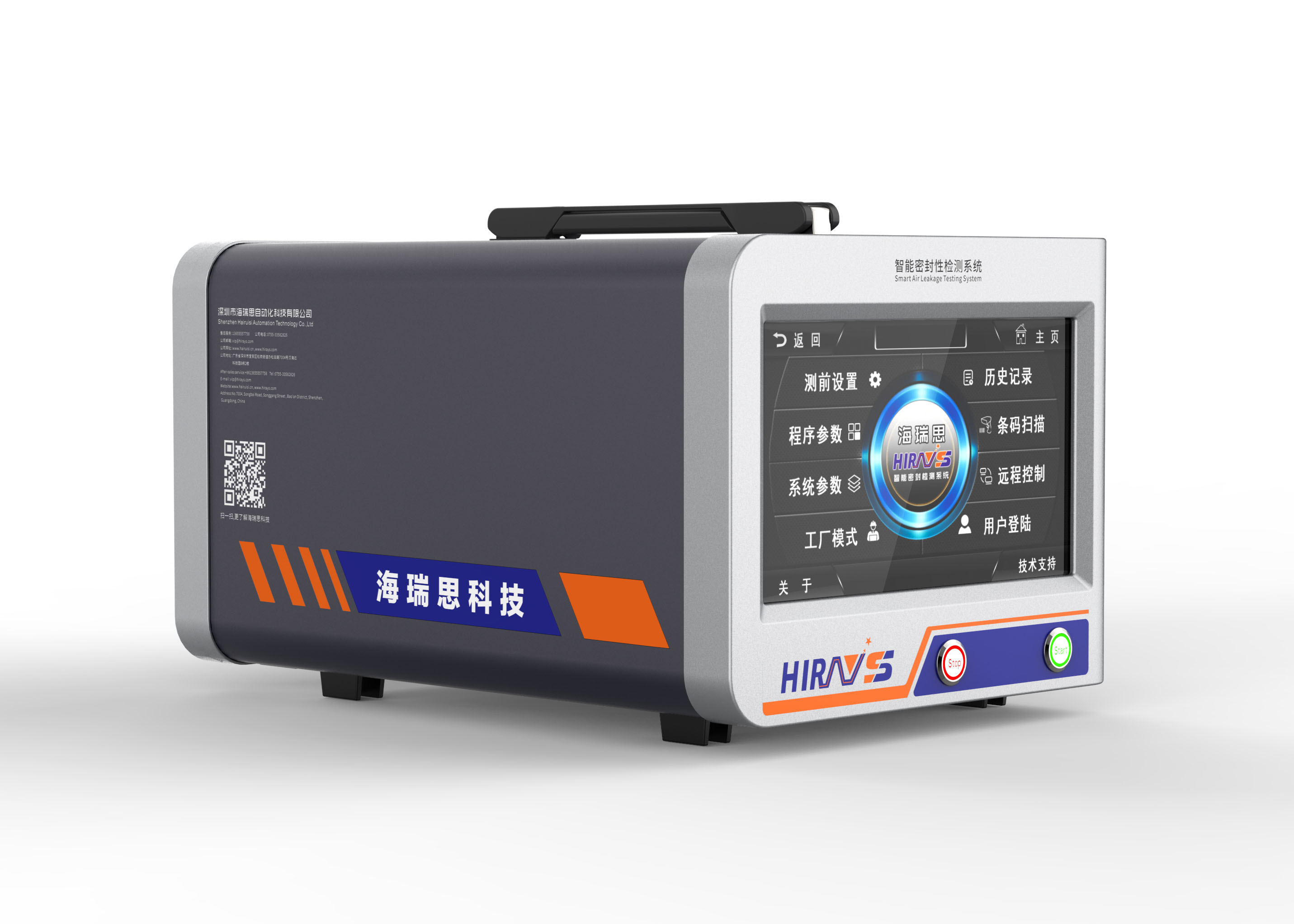

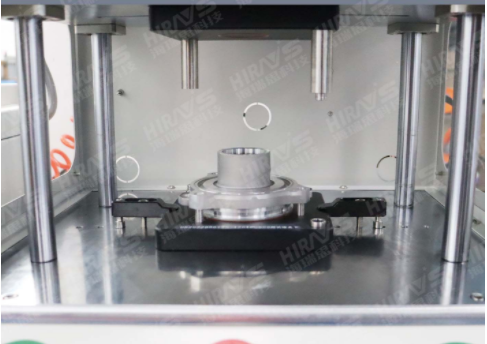

Testing equipment: HC classic series air leak tester machine

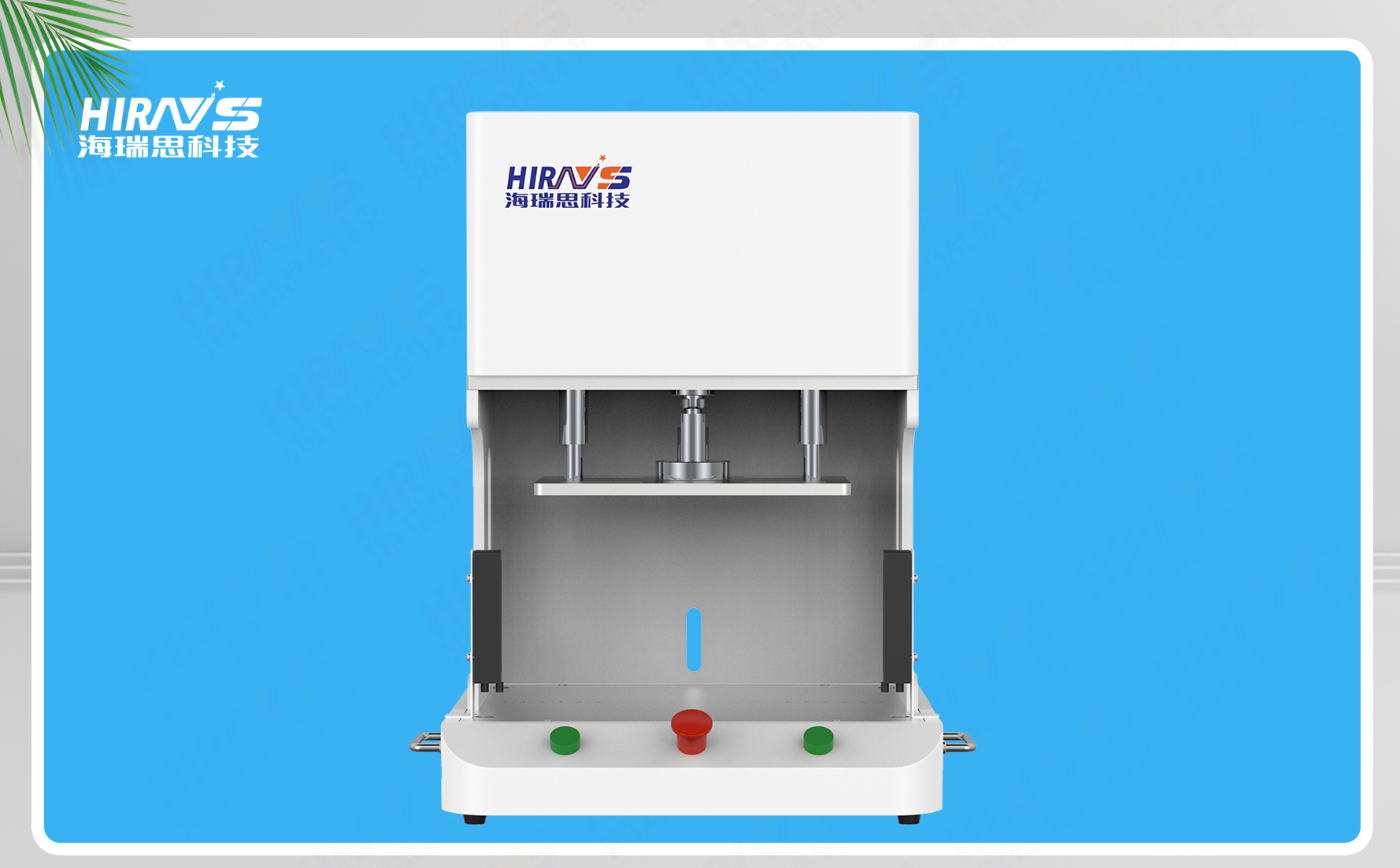

Test method: customize the supporting tooling and fixtures according to customer needs and product structure.

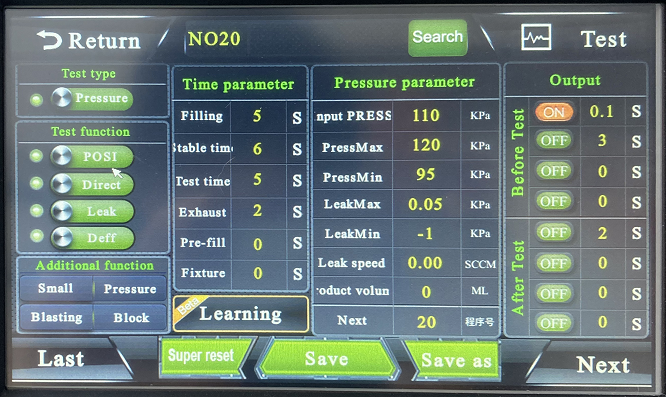

Using the direct test function, put the product to be tested into the mold, The INPUT PRESS is 110Kpa, the Filling time is 5s, the stable time is 6s, the testing time is 5s .During the test, if the leak does not exceed 50pa, the product is qualified.

Profit of Hirays’ water detection equipment

l High precision, ensuring the stability of the mold;

l High resolution, even the smallest leakage can be accurately detected ;

l Experienced engineers bring sophisticated mold design, so that each mold you use is stable and reliable ;

l All the requirements of air leakage testing can be packaged and purchased in Hirays to reduce the total cost of ownership;

l Strict requirements, bring a stable detection system to help you select defective products ;