Solution of endoscopic leak test

- Model: Solution of endoscopic leak test

- Category: Medical instruments

- details:

When performing internal organ examinations in hospitals, endoscopes are generally used as medical devices as auxiliary tools.

With the development of image collection technology, the development level of endoscopic technology has also become better, because the quality of the image directly affects the use of endoscopes. Endoscopes enter the body through natural orifices in the human body or through small surgical incisions. When used, the endoscope is inserted into the pre-examined organ to directly peek into the changes in the relevant part.

The tightness of the endoscope is related to the imaging quality, if the sealing is not good, it is easy to seep water, damage the optical system, and affect the observation. The water valve sheath and the cone of the cystoscope should be tightly fitted, otherwise it is easy to leak and affect the operation, endangering the safety of patients.

Testing requirements

Parts to be tested for optical hard tube endoscope:leak detection of eyepiece, objective lens and shell (finished product testing) Test pressure: 150-200Kpa;

Electronic soft endoscope to be tested: leakage of lens and cable (semi-finished product testing) Test pressure: 10-15Kpa

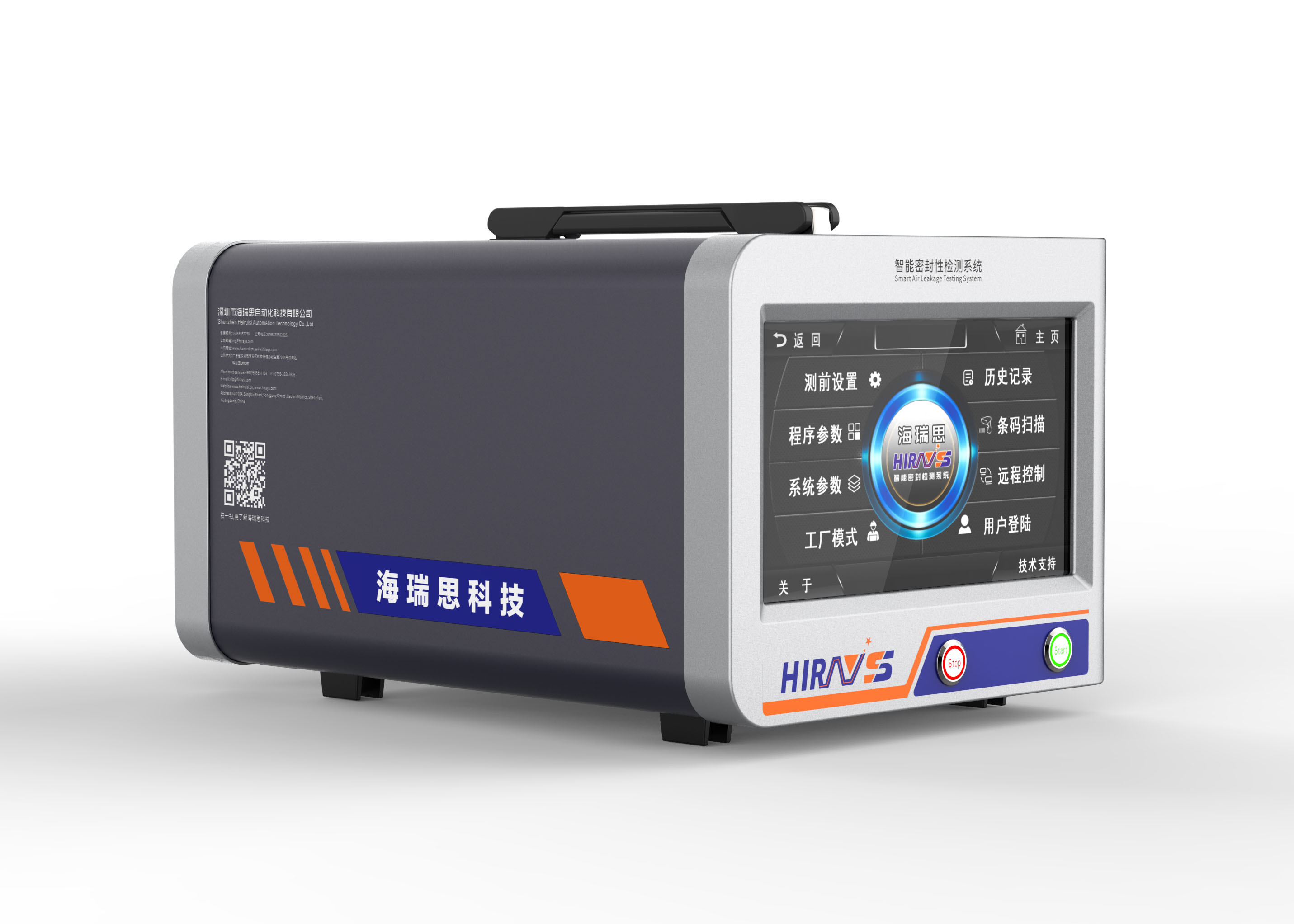

Air leak test system

Air leak test system =instrument +tooling (optional) +mold (optional)

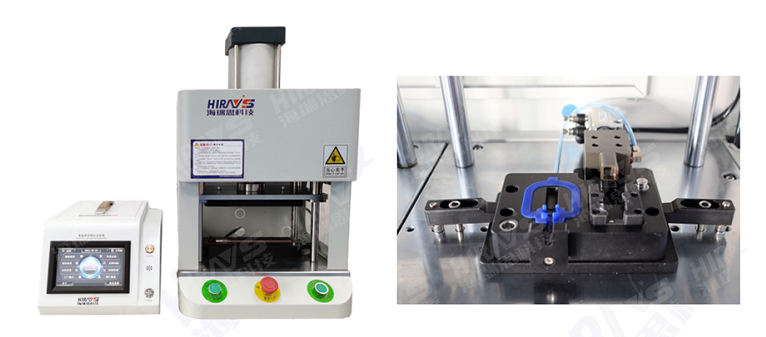

Optical hard tube endoscope Model: HC-B2010MAA leak tester + desktop type large tooling + customized mold

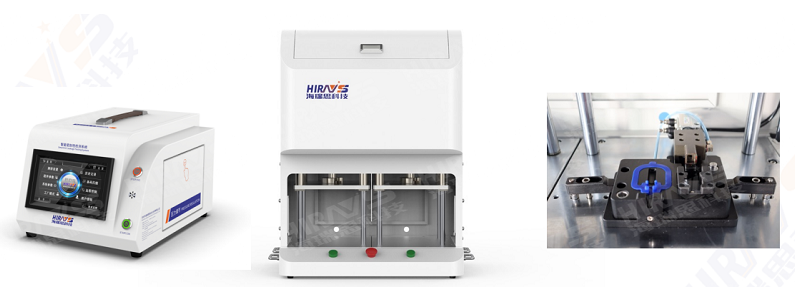

Electronic soft endoscope model: HC-B2010MAA leak tester + tabletop double-station tooling + customized mold

Difficulties met in detection:

Problem 1: It is very difficult to make the mold for the lens inspection of electronic soft endoscope. If the mold is not well made, it is easy to make a mistake.

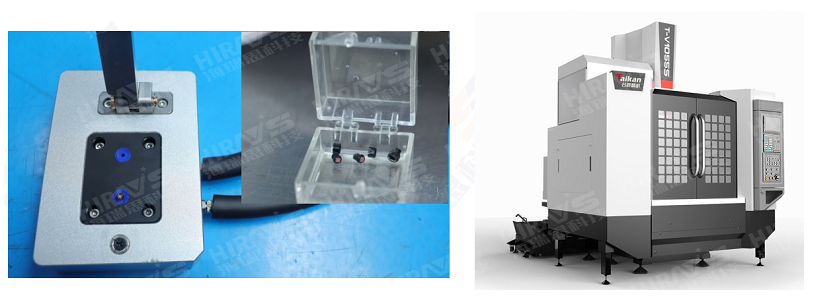

Solution: Hirays has more than 30 experienced mold design engineers and 8 high-precision CNC machining centers. The machining accuracy can reach 0.02 mm;

Problem 2: The lens and lens body of the electronic soft endoscope are generally soaked in 1.2-1.5m water depth, which is time-consuming and water consuming. After the test, the product should be dried and dried;

Solution: The Hirays’ leak testing system is used to perfectly solve the problems of labor, water consuming and labor.

Reasons for choosing us

Advantages of Hiray endoscopic leak test solution:

l High precision mold processing , up to 0.02mm;

l Air leak tester, resolution up to 0.1PA;

l Hirays allows your controller to be tested in one testing equipment;

l Hirays has more than 30 mold design engineers and a strict evaluation system;

l The designed detection system strictly considers the stability and accuracy of the test results;

Benefits of Hiray endoscopic leak test solution:

l High precision, ensuring the stability of the mold;

l High resolution, even the smallest leakage can be accurately detected ;

l Experienced engineers bring sophisticated mold design, so that each mold you use is stable and reliable ;

l Instant communication with Hirays, can save the pain of looking for contacts everywhere ;

l Strict requirements, bring a stable detection system to help you select defective products ;