Does the lamp die casting need to be tested for air leakage? How to test?

- Model: Does the lamp die casting need to be tested for air leakage? How to test?

- Category: Others

- details:

There are more and more application scenarios for lamps, and most of these lamps are different.

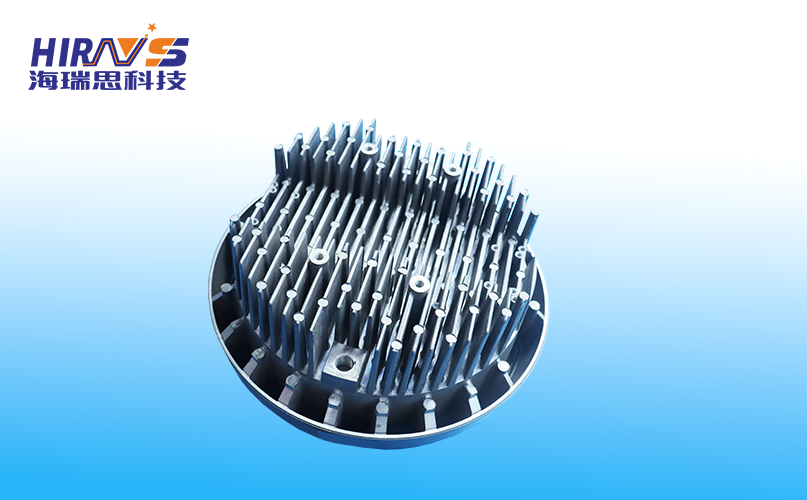

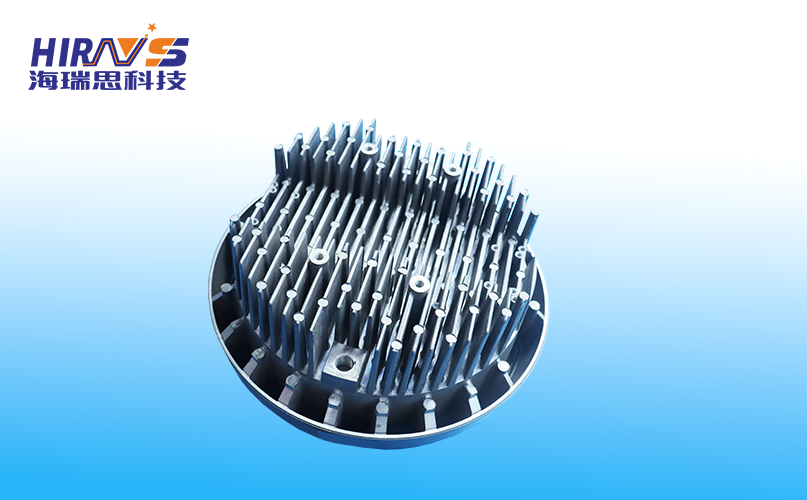

In particular, the material of the lamp is not only plastic material, but also metal material. The lamp requires a certain degree of leak test, in order to avoid the die casting of the lamp may have a sand hole, which may cause damage to the internal circuit of the finished lamps due to short circuit, it is necessary to test the air leakage of the die casting of the lamp.

Today, we will share the air leak testing methodsof lamp die castings.

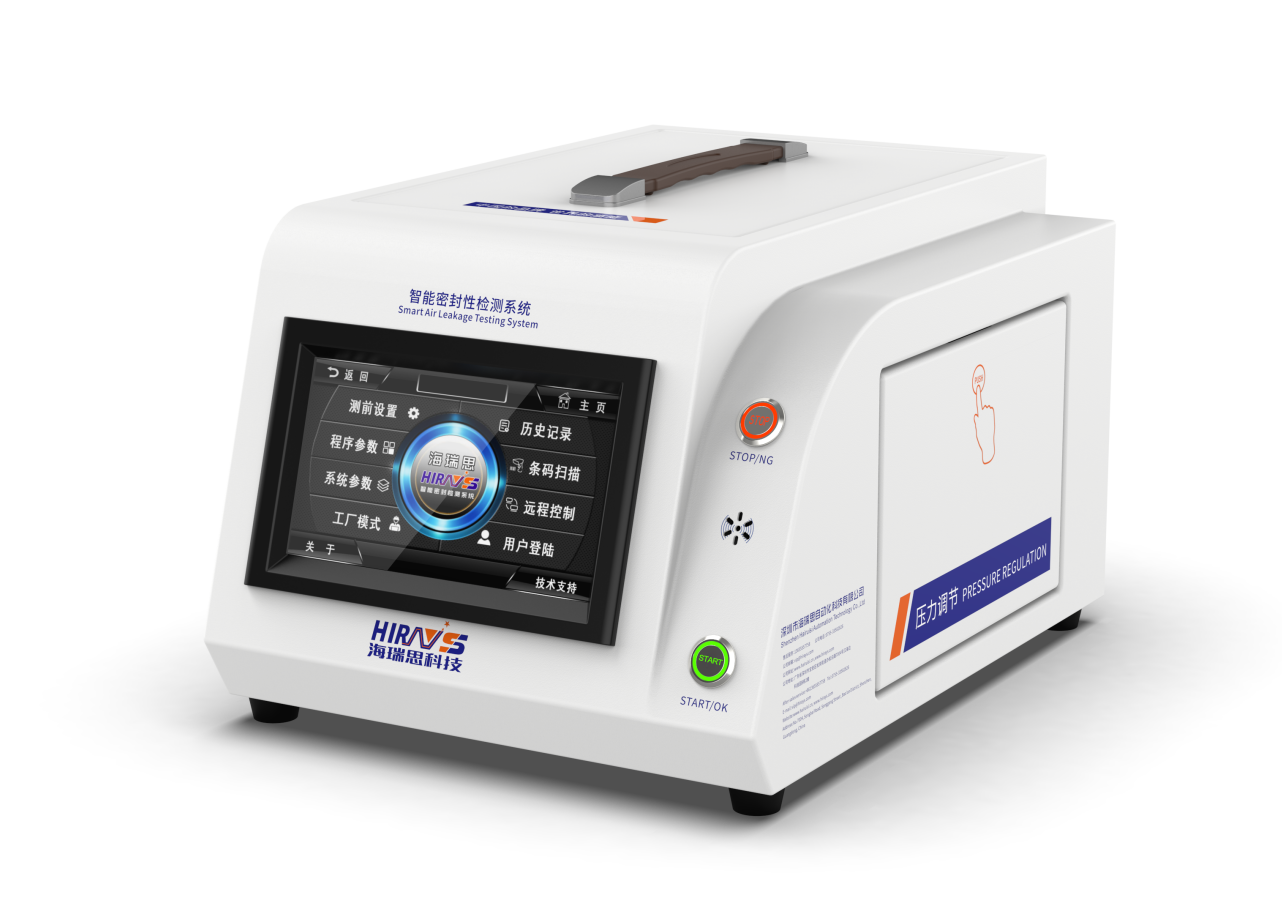

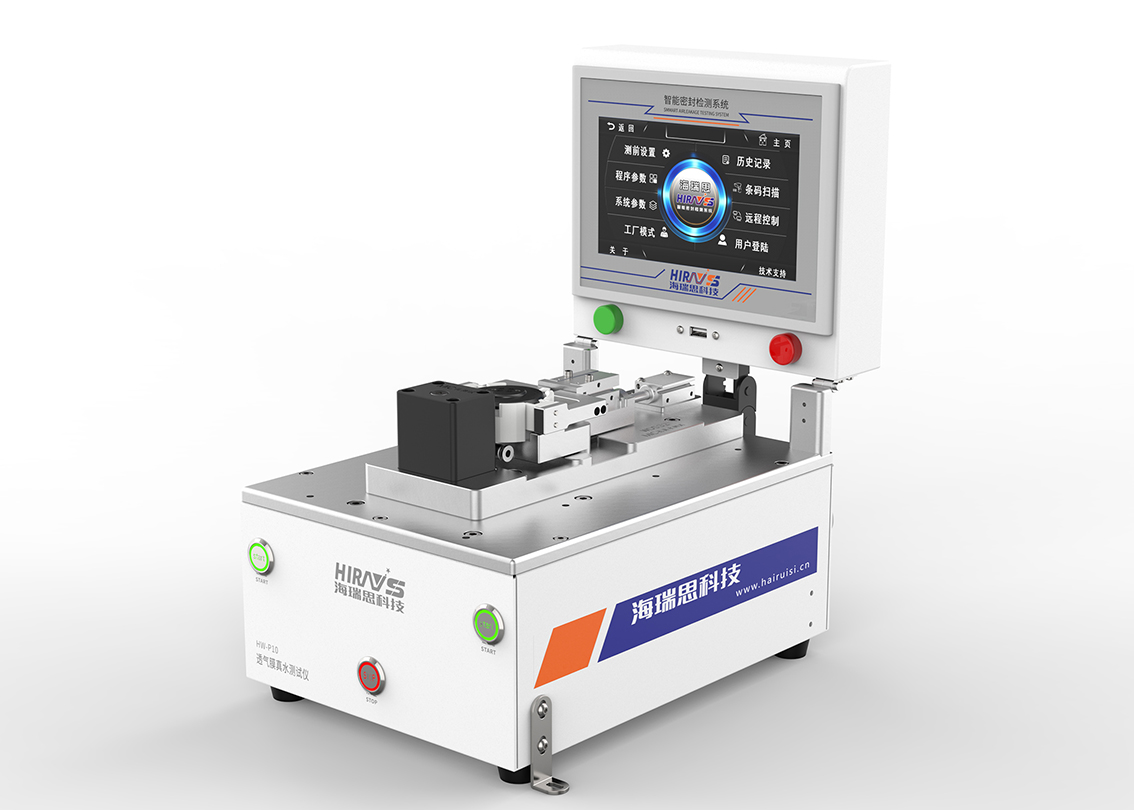

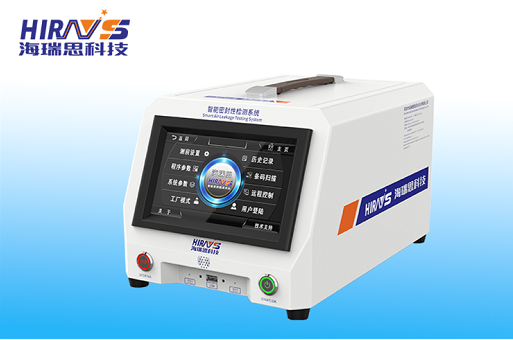

Testing equipment: HC classic series air leak tester

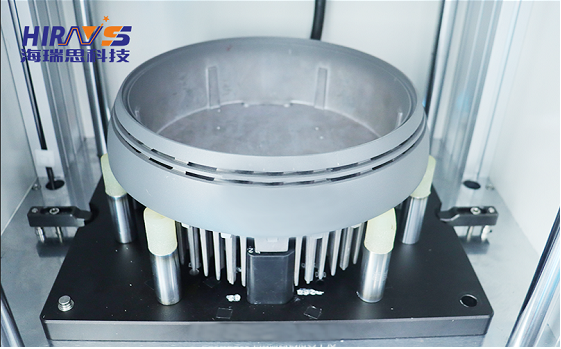

Solution: Design the mold and tooling according to the shape of the die-casting part of the lamp and customer requirements.

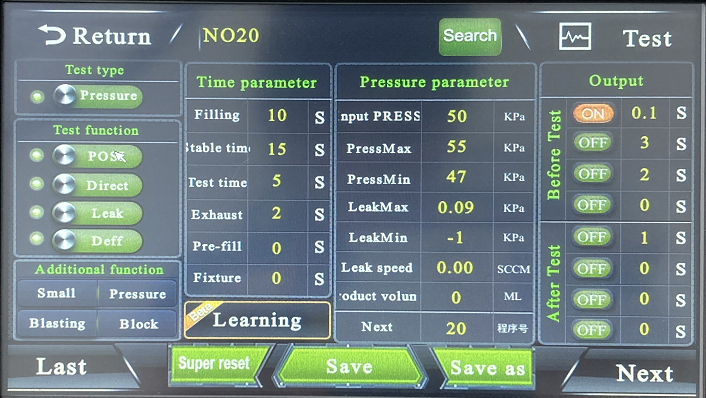

Using direct test function, put the lamp die casting parts into the mold, after pressing the start button, the instrument enters the test program, the Input PRESS is 50Kpa, the Filling time is 10s, the Stable time is 15s, and the test time is 5s. The leak max is 0.09Kpa.

Advantages of Hirays’ air leak tester equipment:

l High precision mold processing , up to 0.02mm;

l Air leak test, resolution up to 0.1PA;

l Hirays has all product lines of air leak tester, real water detection and HE leak detector, which can meet the use scenarios of all leakage tests from trial production to mass production;

l Hirays has the ability of rapid system integration, and can deliver goods within 7 days as soon as possible after placing an order;

l The designed testing system strictly considers the stability and accuracy of the test results;

Profit of Hirays’ air leak tester equipment:

l High precision, ensuring the stability of the mold;

l High resolution, even the smallest leakage can be accurately detected ;

l All the requirements of air leakage testing can be packaged and purchased in Hirays to reduce the total cost of ownership;

l Quick response, when the internal process is completed, the test equipment is just finished;

l Strict requirements, bring a stable testing system to help you select defective products ;