How is the air leak test done for medical bags?

- Model: How is the air leak test done for medical bags?

- Category: Medical instruments

- details:

The common medical bag instruments include infusion bag, urine bag, blood-pressure cuff, oxygen bag and blood bag, which are generally used to hold liquid or gas.

Bag products are generally made of PVC materials and processed by high cycle heat sealing machine. If its air leakage is not good, it will cause gas or liquid leakage, which may affect the use experience, or threaten human life safety, causing immeasurable losses.

How do we test whether the medical bag leaks?

Air leak test process

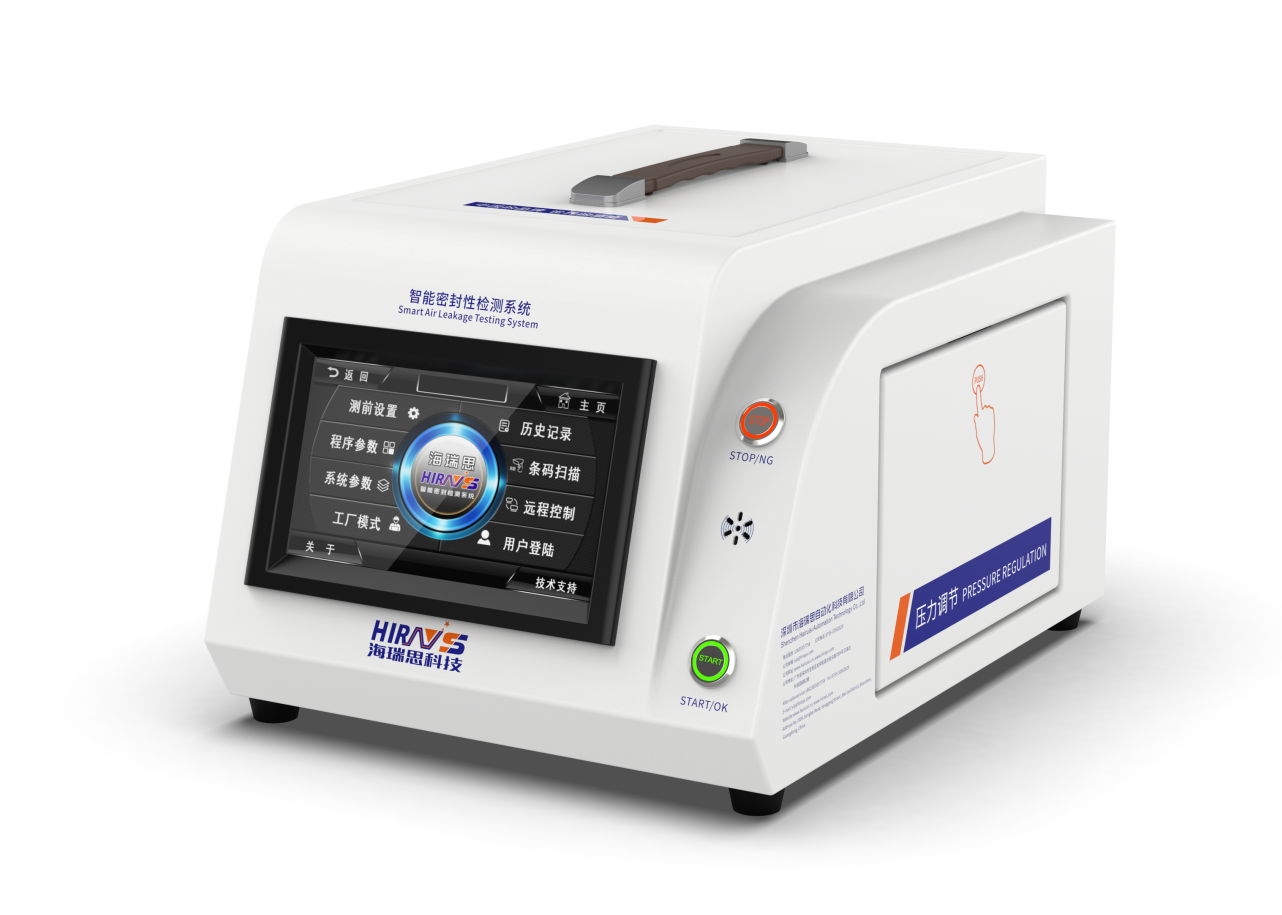

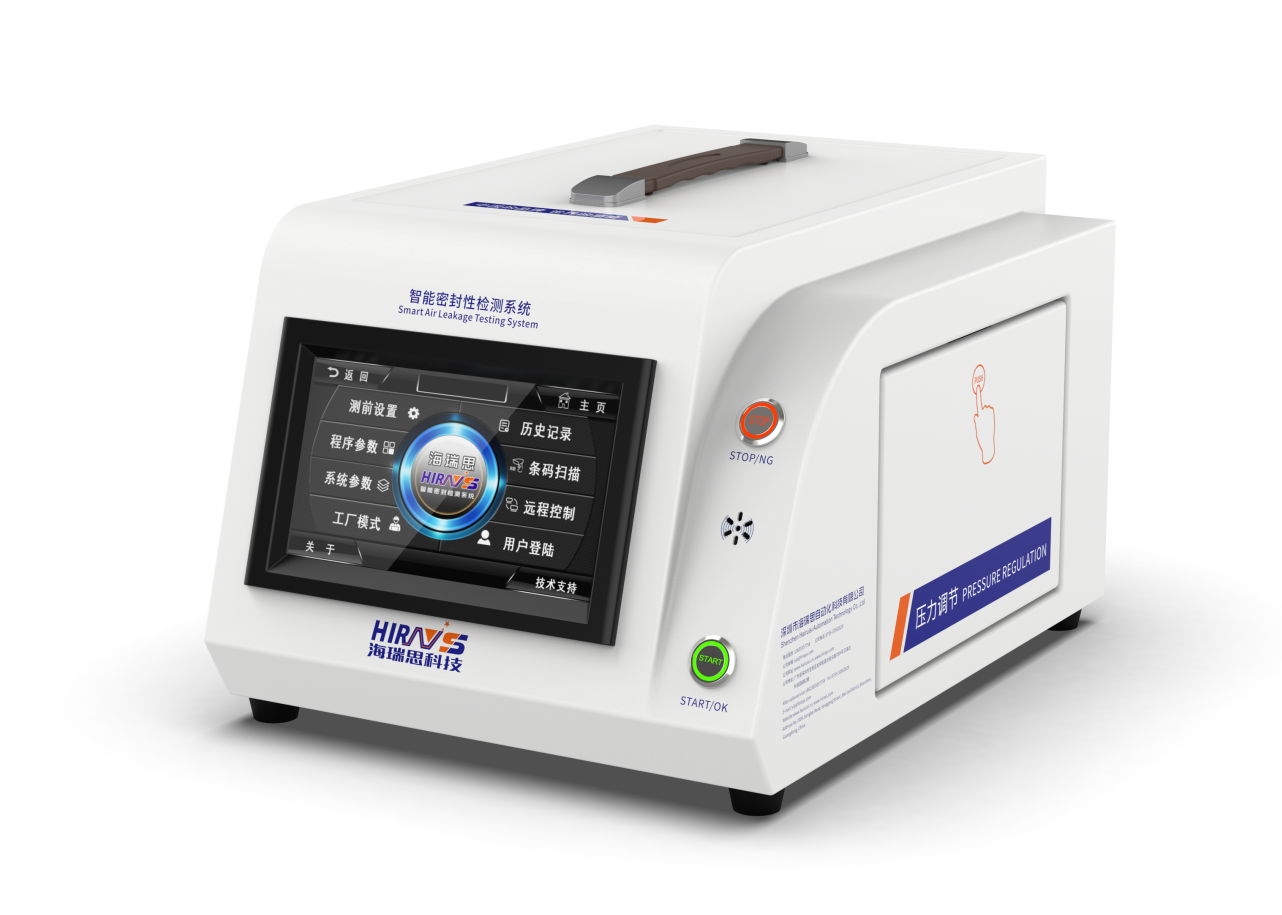

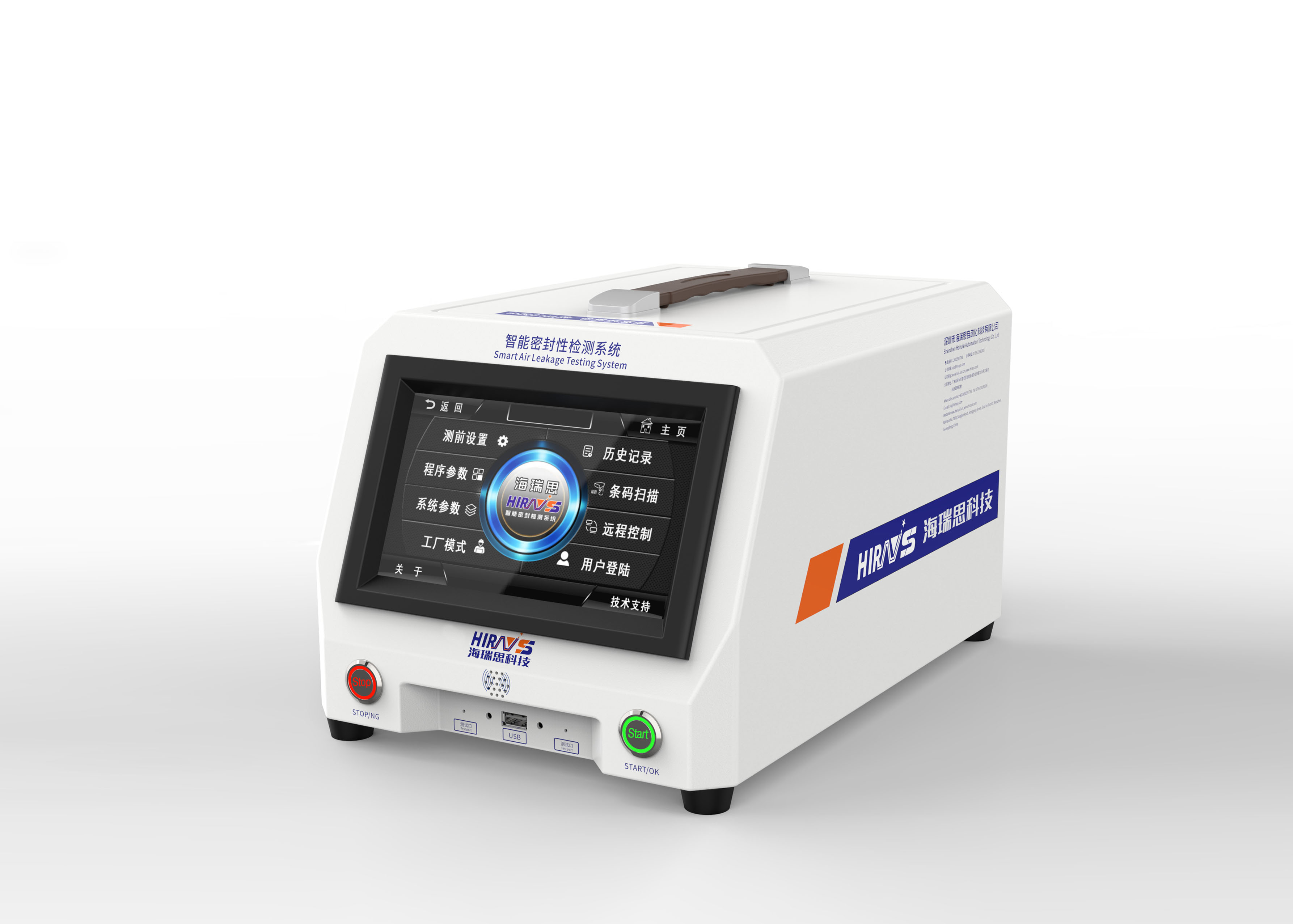

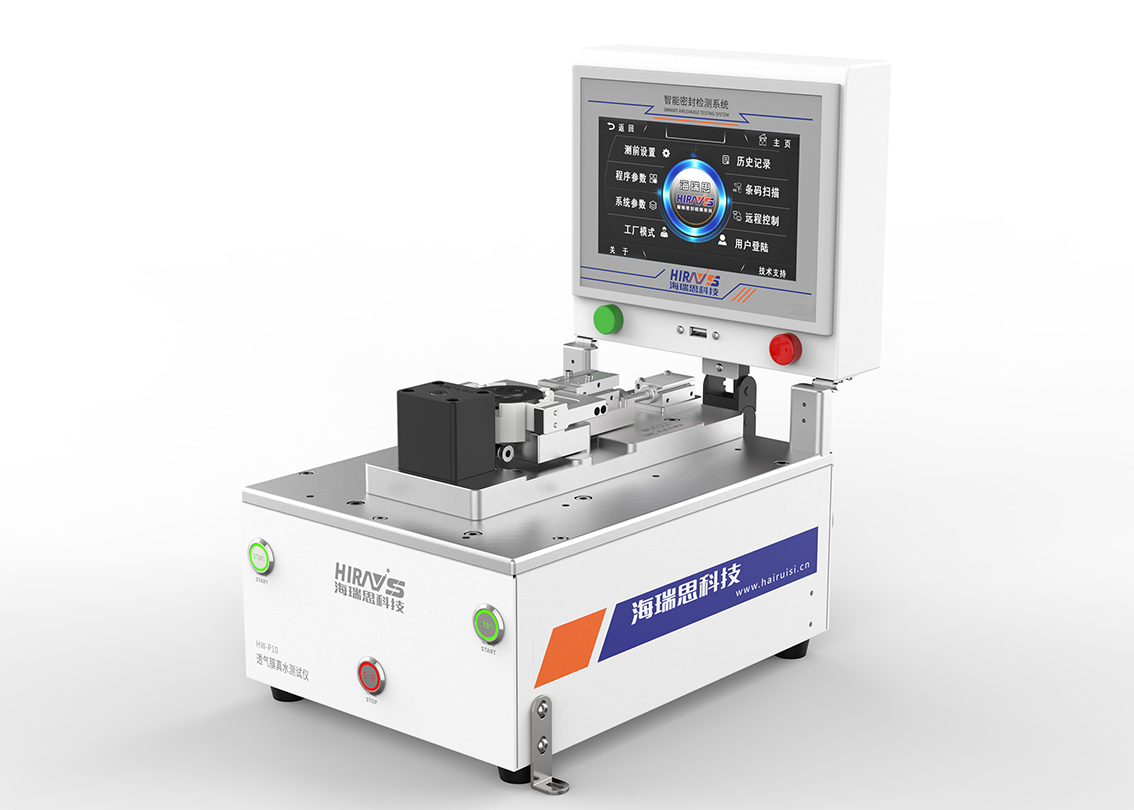

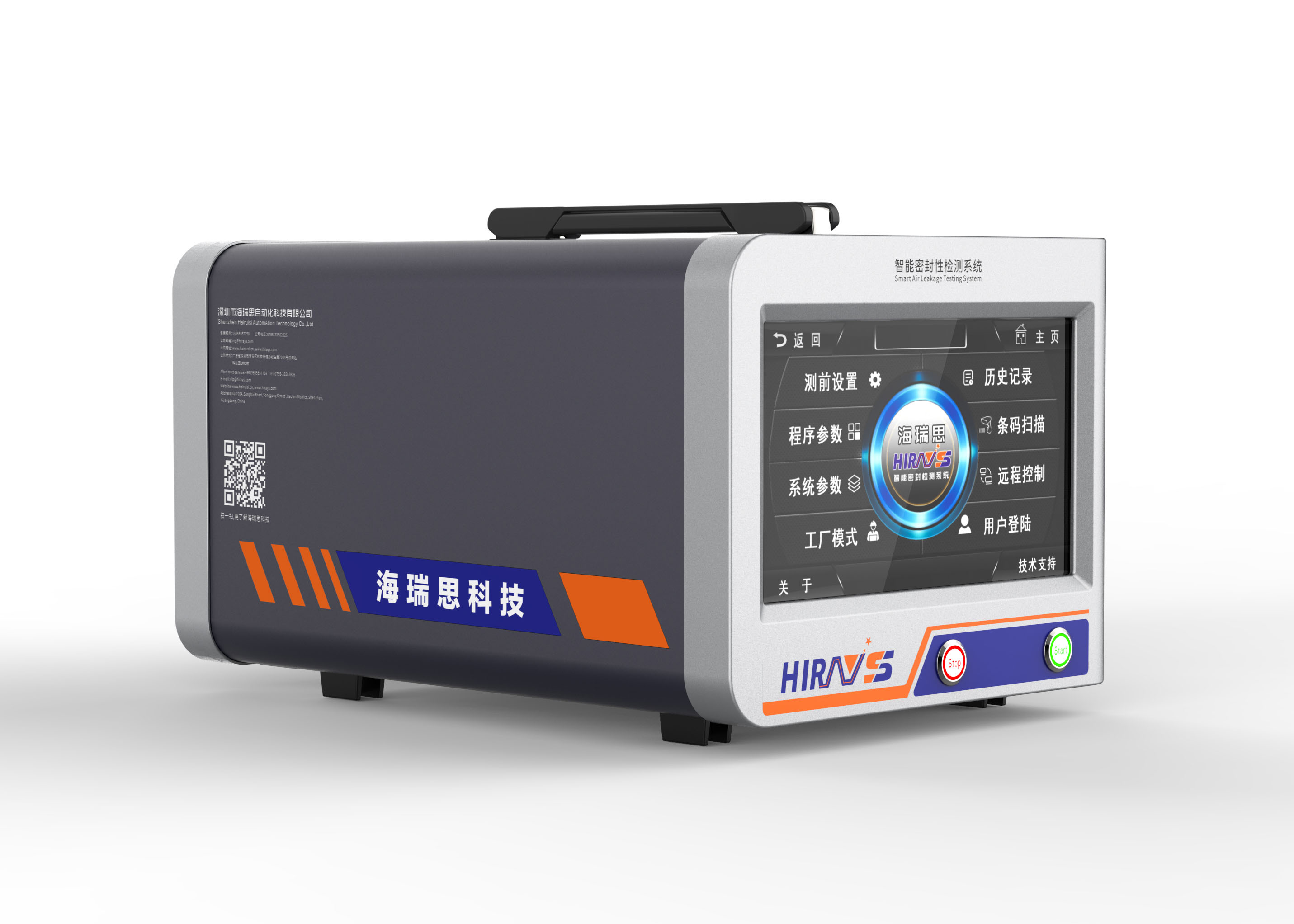

Testing equipment: HC classic series air leak tester machine

Detection method: direct detection is adopted with customized molds and tooling as customer’s need. Place the product to be tested on the fixture, and press the start button to start the test.

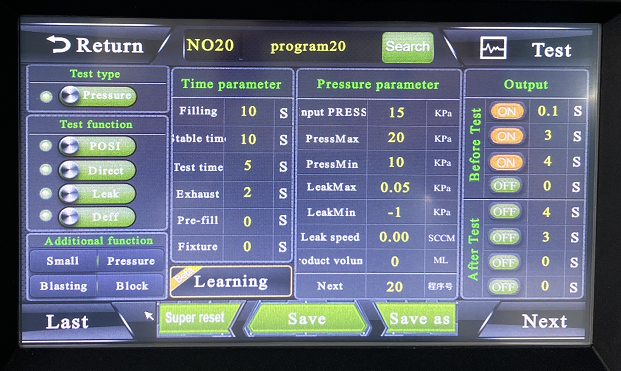

Test parameters: inflation 15Kpa, time 10s, voltage stabilization 10s, test 5s. In this process, if the leakage exceeds the upper limit of 50pa, the program triggers an alarm or NG signal appears, that is, the air leakage of the product to be tested is unqualified, and it is a defective product.

Reasons for choosing us

Advantages of Hirays’ air leak tester machine:

l High precision mold processing , up to 0.02mm;

l Air leak test, resolution up to 0.1PA;

l Hirays has all product lines of air leakage detector, real water detection and HE leak detector, which can meet the use scenarios of all leak tests from trial production to mass production;

l Hirays has the ability of rapid system integration, and can deliver goods within 7 days as soon as possible after placing an order;

l The designed detection system strictly considers the stability and accuracy of the test results;

Profit of Hirays’ air leak tester machine:

l High precision, ensuring the stability of the mold;

l High resolution, even the smallest leakage can be accurately detected ;

l All the requirements of air leakage testing can be packaged and purchased in Hirays to reduce the total cost of ownership;

l Experienced engineers bring sophisticated mold design, so that each mold you use is stable and reliable ;

l Strict requirements, bring a stable detection system to help you select defective products ;

The instrument is right,, the test is not tired! More than 2000 customers have witnessed the development of Hirays, and more than 50 engineers are on call. 7 days fast delivery, is a commitment to you, but also to our own requirements. Choose Hirays is to choose stability and high quality.