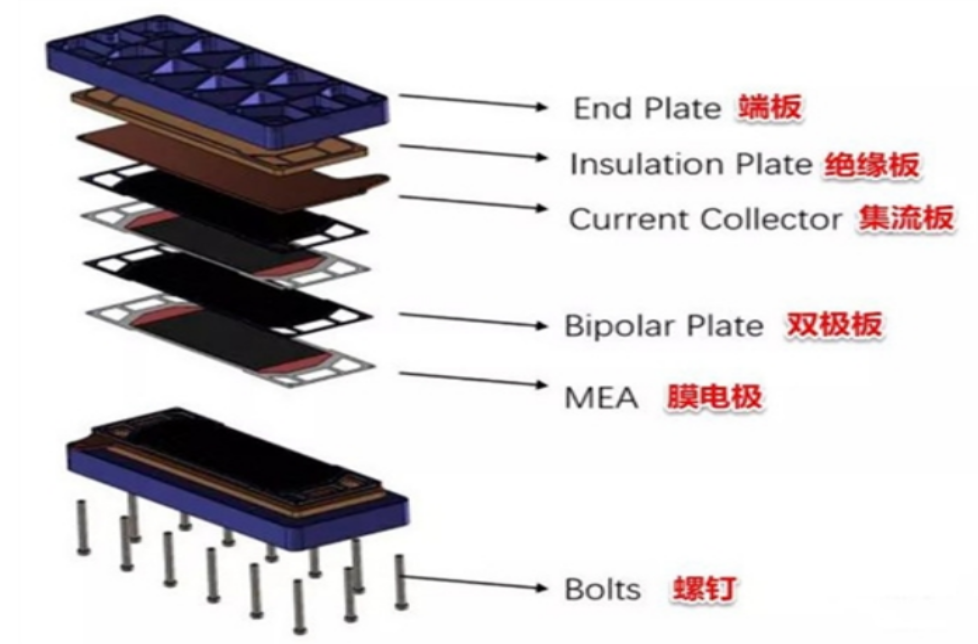

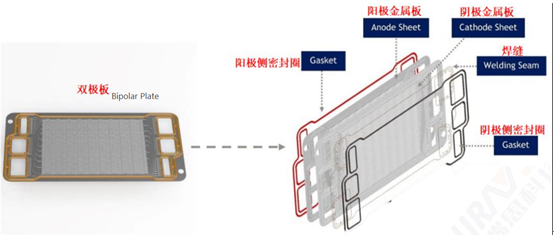

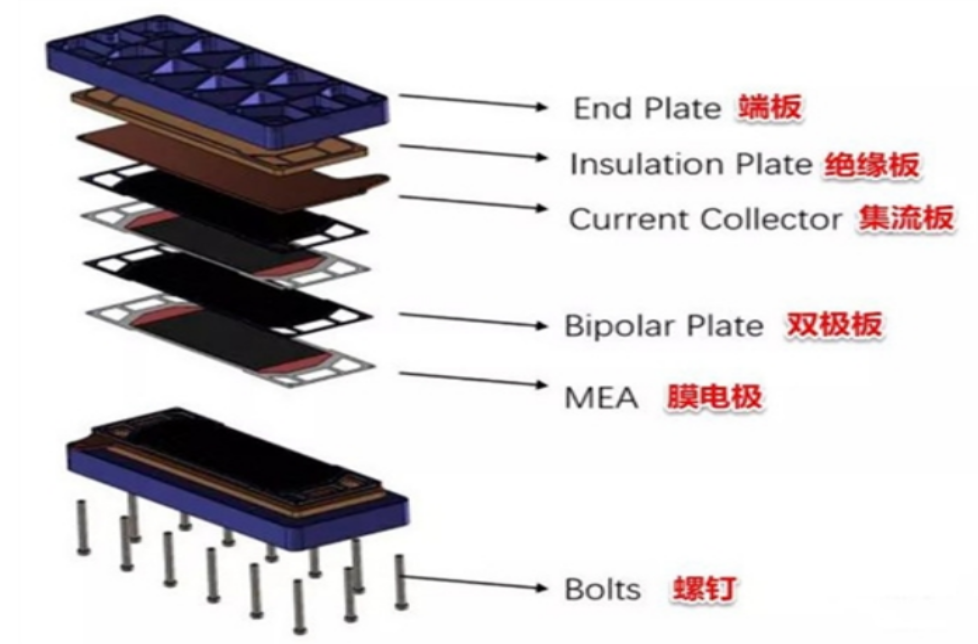

Hydrogen fuel cells are composed of multiple fuel cells stacked in series. That is, the bipolar plate and membrane electrode MEA are superimposed alternately, and the seal is embedded between the monomers.After being pressed by the front and rear plates, they are fastened and fastened with screws.

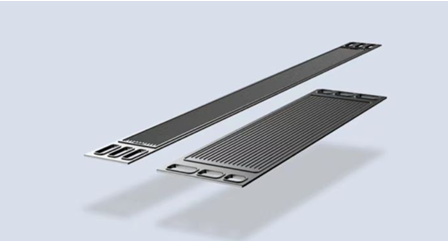

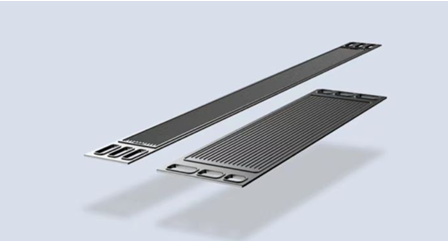

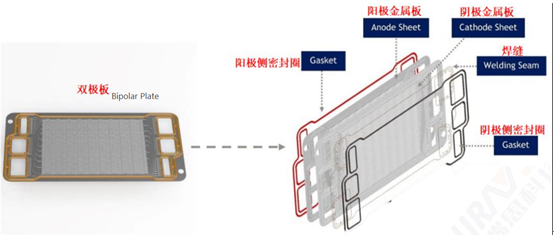

Hydrogen fuel cell bipolar plate

As mentioned above, the bipolar plate is the "skeleton" of the reactor, but it not only supports the reactor, also plays the role of collecting current, raises the channel for the coolant, and separates the oxidant and reducing agent.

Bipolar Plate

Therefore, as the "skeleton" of the hydrogen fuel cell, the bipolar plate needs to pay special attention to its tightness, also known as air tightness.

Ask How does the manufacturer improve the yield of the stack from the aspect of bipolar plates?

Answer:

Ensure that the air tightness of the monomer is qualified, to ensure that each bipolar plate assembled into a finished product is qualified.

Not only the leak test of the stack, but also the cathode plate, anode plate and bipolar plate should be tested separately!

The Composition of bipolar plate and parts to be tested

Bipolar plate is composed of anode side sealing ring, anode metal plate, cathode metal plate, welding seam and cathode sealing ring.

Composition diagram of bipolar plate

Parts to be tested

A.Sealing property of shell material after veneer processing / sealing property of single sealing ring;

B.Measure the tightness of the anode and cathode after welding;

C.Multiple bipolar plates and membrane electrodes are assembled together to measure the air tightness of water channel, oxygen channel and liquid cooling channel.

Hydrogen fuel cell

Air leak test scheme of bipolar plate

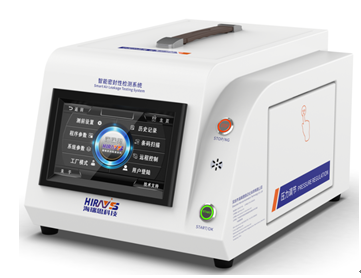

Recommended instrument: Hiray’s HC classic series testing instrument

Usage: according to the bipolar plate parts and the overall structure, different molds are developed.

Install the mold on the customized tooling, and then put the tested product into the mold.

Select the set program to start detection. The instrument must determine whether the tested object is OK or NG according to the set procedure.

Test process: clamp → start → stabilize pressure → test → bleed → remove the product.

Inspection work before mass inspection

1: Air leak test

Put the assembled bipolar plate into the air leakage testing equipment of the preliminary setting procedure for testing, and record the "test pressure" and "leakage value";

2:Soak water detection

Throw the bipolar plate into the water after detection, observe the actual leakage, and record the phenomenon and result;

3. Comparison of gas inspection and water detection:

Analyze the air leak test data and water immersion test data, and revise the air leakage test equipment program;

4. Mass inspection:

Start mass testing, then gradually improve the process and testing procedures.

What should a complete detection system have?

As shown below:

1. Factory end: air compressor, air storage tank, filter, Refrigerant dryer, adsorption dryer and pipeline;

2. Testing end: air leak testing instrument, testing tooling and customized testing mold.

Reasons for choosing Hirays

Delivery capacity of Hirays:

Instrument materials, 200-300 sets in stock;

Perfect quality control;

Trained assemblers;

Capacity: 8 sets / person / day;

Conventional instruments, 15 in stock;

Hirays’ HC classic series multi-channel air leak tester machine

The delivery time is the fastest among peers, and it only takes 0-1 days to deliver;

Improve the operator's satisfaction with the working environment;

The air leakage test equipment is stable and accurate, reducing the labor intensity of factory commissioning personnel;

It can provide early trial production verification, and quickly improve the production process and speed up the project progress;

Worry free after-sales, providing 24 months warranty period;

Compared with foreign counterparts, more competitive price, to ensure the overall project to achieve greater benefits;

Local technical support, door-to-door service within 4 hours in the province, and door-to-door service with partners outside the province within 4 hours.

The instrument is right,, the test is not tired! More than 2000 customers have witnessed the development of Hirays, and more than 50 engineers are on call. 7 days fast delivery, is a commitment to you, but also to our own requirements. Choose Hirays, is to choose stability and high quality.