How can we check whether the waterproof performance of the motor and battery is good?

This requires the use of an air-leakage test, which is also a waterproof detection device, to test the motor and battery pack.

The locations to be test

The locations to be test for motor:

Air leak test of motor assembly: end cover and casing dispensing point, test pressure: 20-30kpa

Air leak test of stator water cooling pipeline: water cooling pipeline of casing, test pressure: 200-400kpa

Air leak testing of battery pack

Parts factory, test the air leakage of shell / water cooling pipe, test pressure: 10-15kpa / 200-300kpa

Test the air leakage of the shell, test pressure: 10-15kpa; VOC detection mode, vacuum pressure - 90kpa

Assembly factory: air leakage test pressure of the whole package: 5-7kpa

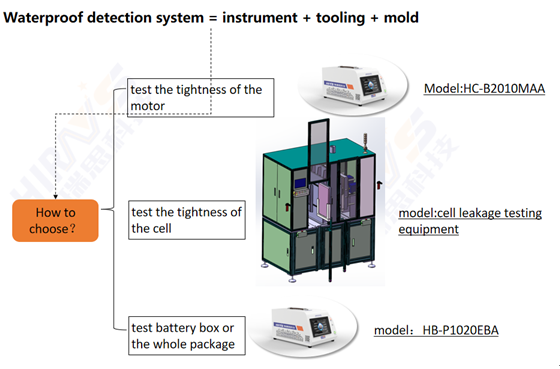

The components of air leak test system

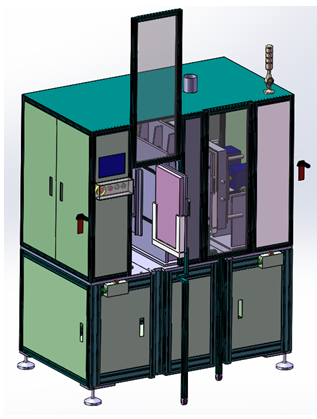

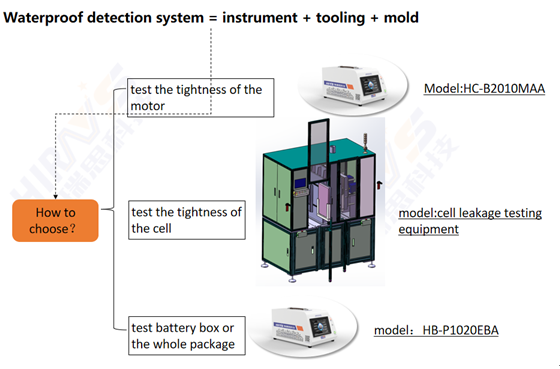

Components of water detection system

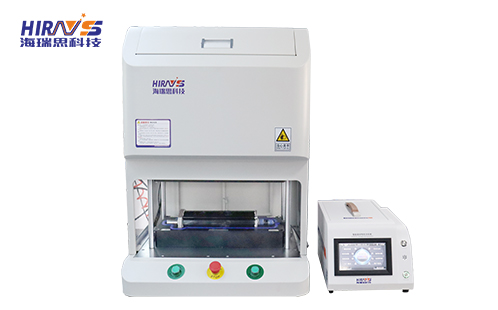

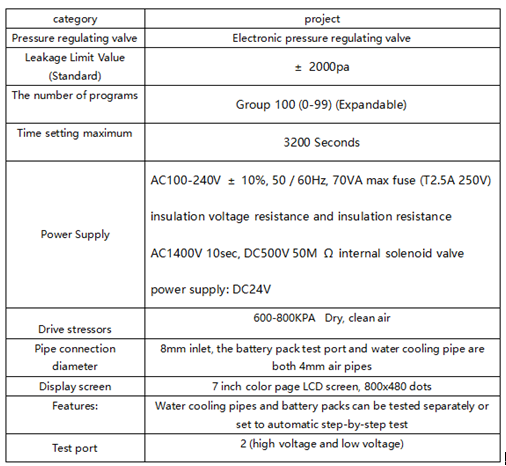

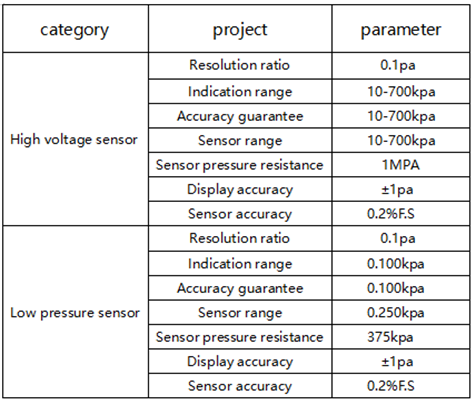

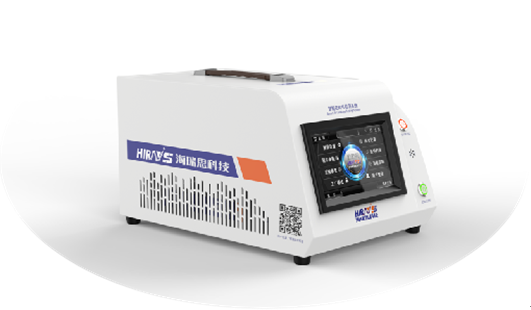

As shown in the figure above, the model of the air leakage test for detecting the motor tightness is HC-B2010MAA;

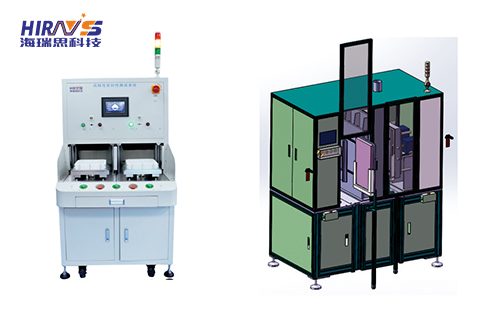

The waterproof testing equipment for testing the air leakage of the cell is: cell leakage testing equipment;

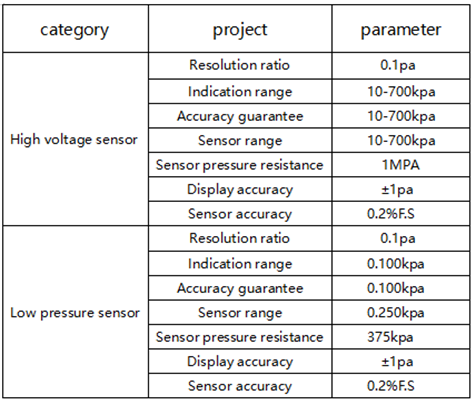

The instrument model for testing the battery pack box or the whole package is HB-P1020EBA;

Problems and solutions that may be encountered in mass production:

Problem 1: The incoming inspection of the motor shell needs to measure the high pressure of 200-300kpa. After the motor shell is assembled, the tightness of shell needs to be measured. Only 10KPA is needed. Now, the pressure is manually adjusted every time,and it can only be measured one by one, which is very troublesome and time-consuming.

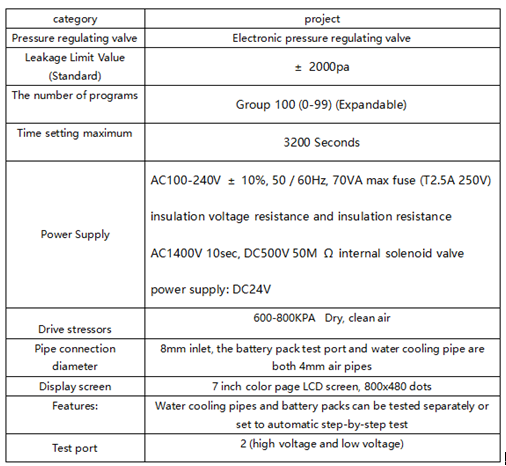

Problem 2: After the battery is packaged, the water-cooling pipes and the whole package must be tested for air leakage. Now, it is also tested one by one which is very troublesome, because the whole package test takes a long time.After the whole package is tested, whether the water cooling pipe is qualified, sometimes forgotten.

Solution: Hirays’ HB-P1020EBA special leakage testing instrument for battery pack.

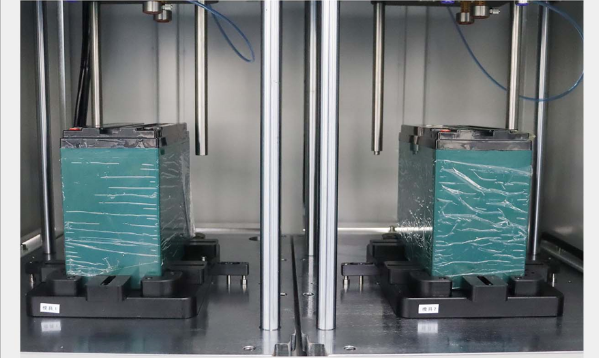

Problem 3: During the production process of the cell, because the electrolyte is filled, it is impossible to use the air leakage method to test. How to control the tightness of the cell?

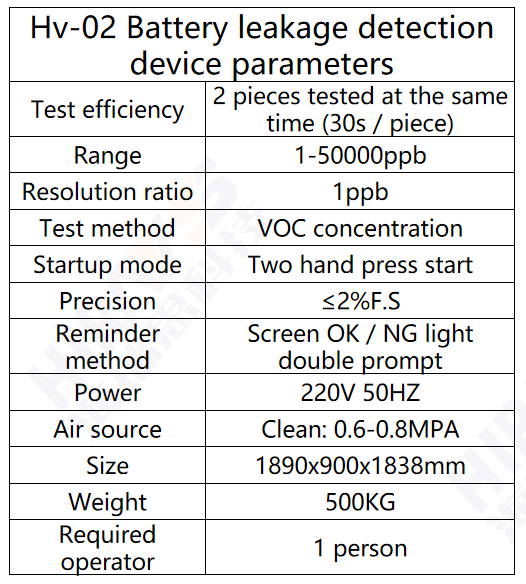

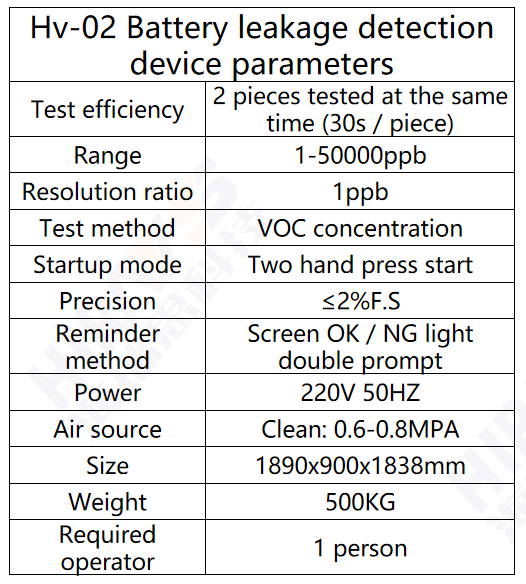

Solution: Hirays’ HV-02 special leakage testing instrument for battery pack, suitable for square power battery / cylindrical battery.

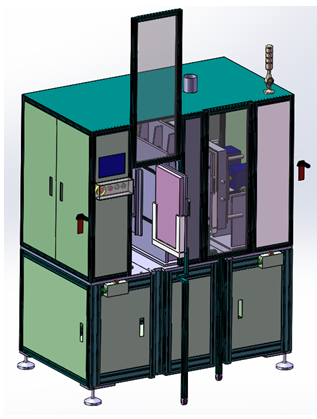

Auxiliary tools: as shown below

Reasons for choosing us

Advantages of Hiray’s motor and battery pack testing solution:

1. The detection precision can reach 1 ppb (1 billionth);

2. Eliminate the influence of humidity and temperature;

3. The upper computer Standard Version (free) can adapt to most use scenarios;

4. Hiray has the ability of rapid system integration, and can deliver goods within 7 days after placing an order;

5. The designed detection system strictly considers the stability and accuracy of the test results;

The benefits brought by Hirays’ motor and battery pack testing solution:

l High precision,even the smallest leakage can be accurately detected ;

l Even if the temperature and humidity change, the detection data will not fluctuate violently;

l In 70% of cases, no customized development is required, saving time and cost;

l Quick response, when the internal process is completed, the test equipment is just finished;

l Strict requirements, bring a stable detection system to help you select defective products ;

Cooperative customers