Electric vehicle vacuum water pump 's leak test

- Model: Electric vehicle vacuum water pump 's leak test

- Category: new energy vehicles

- details:

With the demand for convenient urban travel and the rising oil price, the market of electric vehicles is expanding.

The two pumps are an integral part of an electric vehicle, one is a vacuum pump for power supply and the other is a water pump for circulating cooling.

Pump

The braking system of vacuum pump, passenger car and light commercial vehicle adopts hydraulic pressure as the transmission medium, which provides excellent braking performance for the driver to compare with the pneumatic brake system that can provide power source.

Vacuum pump

The water pump in electric vehicles is generally an electronic water pump (also known as "electric water pump"), which is mainly used for circulating cooling of drive motors, electric components, power batteries, etc.

If the leak test of these two pumps is not done well, leakage will occur, which will endanger the safety of car driving and social security.

Therefore, the process of air leakage test shall be completed before the air pump components leave the factory.

Part to be tested

Part to be tested of the semi-finished product: whether there are blisters at the injection molding part of the volute/aluminum die-casting (semi-finished product testing), test pressure: 200-300Kpa;

Part to be tested of the finished product of the pump : the joint of the shell (semi-finished product testing) 200-300Kpa;

Part to be tested of Vacuum pump volute: whether there are blisters in aluminum die casting (semi-finished product testing) Test pressure: -90 to -80Kpa;

Part to be tested of vacuum pump: joint of volute (semi-finished product testing) Test pressure: -90 to -80Kpa;

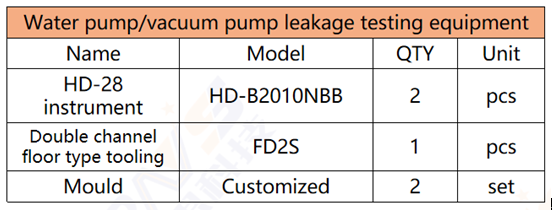

Air leak testing system

Air leak test system = instrument + tooling (optional) + mold (optional)

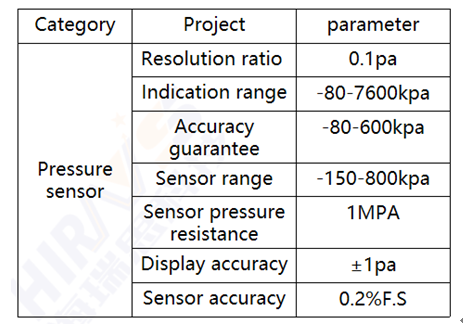

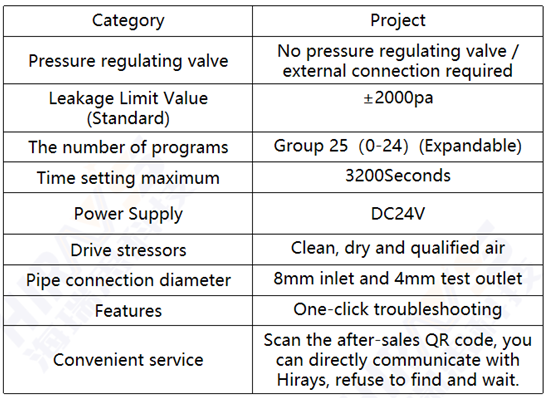

Pump/vacuum pump air leak test device parameters

Problems and solutions that may be encountered in mass production:

Problem 1: All air leak test, requires rich experience in mold design ,processing,and assembly. It is difficult for ordinary air leak tester manufacturers to hire experienced designers, programmers and operating technicians with rich processing experience, resulting in the produced mold itself is not sufficiently tight, resulting in frequent mismeasurements and line stoppages.

Solution: Hirays has more than 30 experienced mold design engineers and 8 high-precision CNC machining centers; The machining accuracy can reach 0.02mm;

Problem 2: If there is a problem, it is difficult to find the contact information of the person in charge of the manufacturer. Some problems need to be communicated for a long time before results can be obtained!

Solution: Hirays pays attention to the customer’s use experience. We try to shorten the distance between questions and answers. Every instrument,tooling,and equipment of Hirays has a quick communication channel for after-sales customer service; When you encounter a problem, you only need to scan the QR code and contact the after-sales customer service immediately.

Reasons for choosing us

Advantages of the environmental sensing air leak testing scheme of Hirays:

l High precision mold processing , up to 0.02mm;

l Air leak tester, resolution up to 0.1PA;

l Hirays has more than 30 mold design engineers and a strict evaluation system;

l When service is needed, scan the QR code of the equipment, directly talk to the after-sales service personnel of Hirays, and refuse to wait ;

l The detection system designed by Hirays strictly considers the stability and accuracy of the test results.

The benefits brought by the environmental awareness air leak testing scheme of Hirays:

l High precision, ensuring the stability of the mold;

l High resolution, even the smallest leakage can be accurately detected ;

l Experienced engineers bring sophisticated mold design, so that each mold you use is stable and reliable ;

l Instant communication with Hirays, can save the pain of looking for contacts everywhere ;

l Strict requirements, bring a stable detection system to help you select defective products ;

Cooperative customers