How to do the leak test for battery pack?

- Model: How to do the leak test for battery pack?

- Category: new energy vehicles

- details:

01.Battery pack

With the rapid development of modern science and technology and the requirements for environmental protection, new energy electric vehicles have emerged and gradually occupy a larger market.

As the main energy storage element of electric vehicles, the battery pack, is the core component and an important impact on the performance of new energy electric vehicles.

New energy vehicle battery pack

For the sake of vehicle safety, when designing battery packs, battery manufacturers will take corresponding protective measures according to the use environment of vehicles to eliminate potential safety hazards as far as possible.

They also have certain requirements for the waterproof capacity of the battery pack to ensure the safety of the battery pack when it encounters water and wades in the process of driving.

If the battery pack does not meet the requirements of dust and waterproof, the environmental conditions of the cell and electrical components are in an uncontrollable state, which is easy to pose a threat to driving.

Battery pack components: multiple battery cells form a battery module, and several modules are connected in series; And then, the battery management system and the battery thermal management system are built by the box made of aluminum alloy and other materials.

02.Battery pack testing requirements

Part to be tested

The joint of upper and lower boxes, high-voltage electrical connectors, water-cooling pipes and cooling ports (waterproof ventilation holes).

Testing difficulties

A. The battery pack has a large area, a small internal space, and the shell is made of thin material which can bear a small pressure;

B. The battery pack is equipped with a high-voltage connector port and a cooling port. How to effectively block it during testing?

0.3 Air leak test of battery pack

1. If the water-cooled pipeline and the battery pack need to be tested together, the special testing instrument for battery pack of Hirays’HB-P1020EBA should be used. The test cycle is 10min / piece;

2. The single battery pack is also used HB-P1020EBA model to test.the test cycle is 5-10min / piece.

The special testing instrument for battery pack of Hirays’HB-P1020EBA,equipped with electronic pressure regulating valve,manual pressure regulation is not required. Direct test is selected for testing, and no need to do a separate fixture.

3. When the cooling port is selected as the inflation port, it is necessary to plug the high-voltage connector port with male and female docking;

If the high-pressure connector port is selected as the charging port, use the quick connector to block the cooling port.

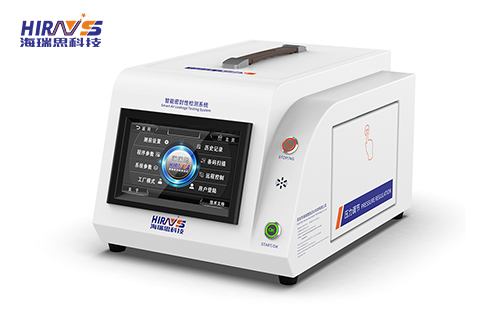

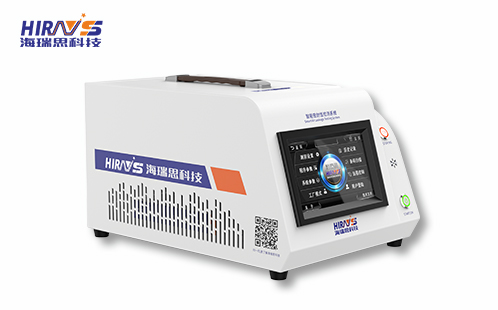

Special testing instrument for battery pack

Usage method

l Connect the air source and power supply, connect the battery pack and the water-cooling pipeline to the instrument, and select the set program to start the test.

l The instrument must determine whether the tested object is OK or NG according to the set procedure.

l Test process: clamp → start → stabilize pressure → test → deflate→ remove the product.

0.4 Hirays’ special air leak testing machines for battery pack

The special testing instrument for battery pack of Hirays’HB-P1020EBA

It is an instrument specially developed for leak testing of new energy vehicle battery pack.

HB-P1020EBA special air leak test machine for battery pack

Advantages:

The integrated high and low pressure detection function can easily test the air leakage of the water-cooled pipeline and the whole package. The combined design is not only saving the use space for customers, but also greatly saving the cost.

The instrument is equipped with an electronic pressure regulating valve, which does not need to adjust the pressure manually, so as to avoid operating errors during detection and damage to the battery pack.

Application range:

Air leak test of the battery pack;

Air leak test of water cooling pipeline of battery pack;

Air leak test of battery pack connector, wiring harness, etc.

The instrument is right,, the test is not tired! More than 2000 customers have witnessed the development of Hirays, and more than 50 engineers are on call. 7 days fast delivery, is a commitment to you, but also to our own requirements. Choose Hirays, is to choose stability and high quality.