How to do the leak test for electric vehicle charging gun?

- Model: How to do the leak test for electric vehicle charging gun?

- Category: new energy vehicles

- details:

The water detection of electric vehicle charging gun and protection box

01 charging gun and protection box

Recently, with the change of international situation, the change of oil price is also by leaps and bounds. New energy vehicles have become the choice of more families.

However, the biggest problem of new energy vehicles is battery charging.When you need to use the car in an emergency, you are often distressed because the electricity is not full. Therefore many consumers are considering carrying charging guns with them.

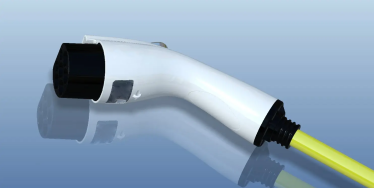

However, when charging, it may be outdoors or in rainy and snowy weather. At this time, the charging gun and the protection box need to have certain waterproof requirements.

That means manufacturers need to test charging guns and protection box for waterproofing before they leave the factory.

02 Testing Requirements

The location to be test for charging gun’s waterproof:as shown in the picture at the gun and wire harness (semi-finished product detection) Test pressure: 10-30Kpa

The location to be test for protection box’s waterproof :box and harness, junction of front and rear boxes (semi-finished product test) test pressure: 10-30kpa

03 water detection

What are the components of the leak testing system?

l Leak test system= instrument + tooling (optional) + mold (optional)

l Instrument: determine whether the data is within the set range, and output the results;

l Tooling: carrying instruments or molds;

l Mold: block or wrap the product to be tested.

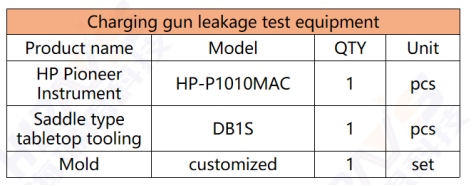

Selection Guide for leak test of charging gun

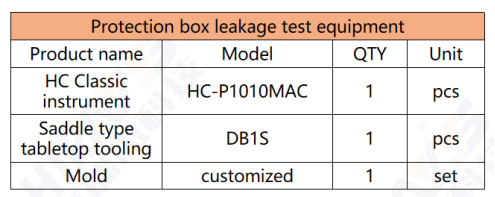

Selection Guide for leak test of protection box

Air leak tester equipment: saddle type tooling

The test process is easier, which solves the problem that the charging cable is difficult to pick and place during the test, while taking into account the stability.

Saddle type tooling - specially designed for leakage test of charging gun / protection box

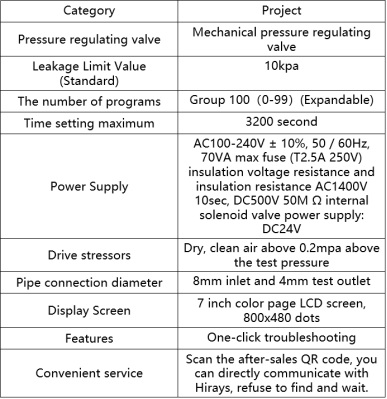

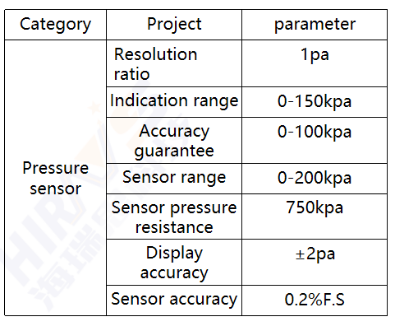

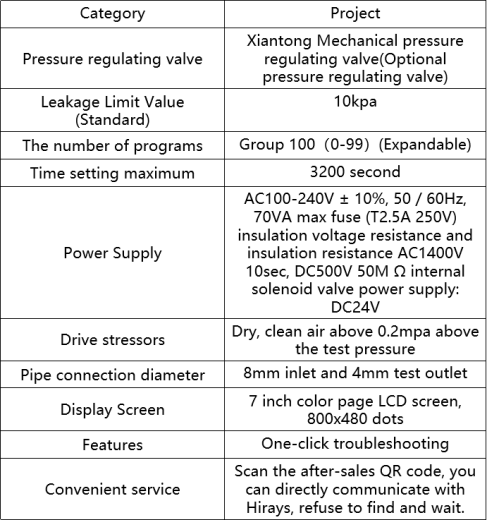

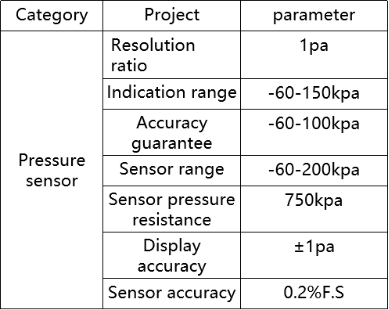

Specification parameters

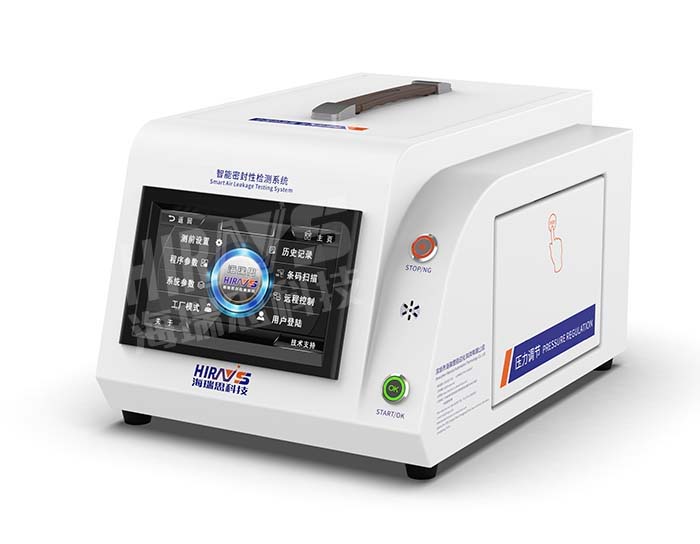

HP-P1010MAC Air leak tester

HC-P1010MAC

04 Water detection solution

Problems and solutions that may be encountered in mass production:

Problem 1: poor stability: during the actual detection, because the charging gun is wired at both ends, the ordinary rack structure can not ensure that it is easy to place and work stably. The test results are sometimes good or bad!

Solution:Air leak testing equipment: saddle type tooling

The test process is easier, which solves the problem that the charging cable is difficult to pick and place during the test, while taking into account the stability.

Saddle type tooling - specially designed for leakage test of charging gun / protection box.

Problem 2: All air leak testing, requires rich experience in mold design ,processing,and assembly. It is difficult for ordinary air leak tester manufacturers to hire experienced designers, programmers and operating technicians with rich processing experience, resulting in the produced mold itself is not sufficiently tight, resulting in frequent mismeasurements and line stoppages

Solution:Hirays has more than 30 experienced mold design engineers and 8 high-precision CNC machining centers; The machining accuracy can reach 0.02 mm;

Problem 3: If there is a problem, it is difficult to find the contact information of the person in charge of the manufacturer. Some problems need to be communicated for a long time before results can be obtained!

Solution:Hirays pays attention to the customer’s use experience. We try to shorten the distance between questions and answers. Every instrument,tooling,and equipment of Hirays has a quick communication channel for after-sales customer service; When you encounter a problem, you only need to scan the QR code and contact the after-sales customer service immediately.

05 Reasons for choosing us

Advantages of Hirays’ water detection equipment

l Unique saddle type tooling design;

l Air tightness detector, resolution up to 0.1PA;

l Hirays has more than 30 mold design engineers and a strict evaluation system;

l When service is needed, scan the QR code of the equipment, directly talk to the after-sales service personnel of Hirays, and refuse to wait ;

l The detection system designed by Hirays strictly considers the stability and accuracy of the test results.

Benefits of Hirays’ water detection equipment

l Bring more relaxed testing experience and improve employees' work happiness;

l High precision, ensuring the stability of the mold;

l High resolution, even the smallest leakage can be accurately detected ;

l Experienced engineers bring sophisticated mold design, so that each mold you use is stable and reliable ;

l Instant communication with Hirays, can save the pain of looking for contacts everywhere ;

l Strict requirements, bring a stable detection system to help you select defective products;

06 How to ensure the accuracy of the results

That is, how to ensure the accuracy ,repeatability and stability of the test results?

l This is determined by the detection result, that is, the displayed OK / NG, while the detection result is determined by the upper and lower limits of leakage, and the factors affecting the upper and lower limits of leakage ( the determination criteria) are the program parameters.

l The judgment standard is made artificially according to the results of the previous experiment.

l Four steps to find standards: first test, then test the water, set standards (small batch trial production), improve standards (mass production)

l What are the factors that affect the judgment standard value?

In other words, when designing the test system, do you consider the following possible fluctuations? And avoid it in time?

l How much is the temperature change of the detected gas during the calculation of the leakage value?

l During the calculation of leakage value, whether there is relatively large deformation of the seal, resulting in larger or smaller space of the measured gas? (Overpressure of seals, easy deformation of products, etc.)

l Has the seal reached its service life and been excessively worn? Are the seals cleaned in time or covered with dust?

Cooperative customers

The instrument is right,, the test is not tired! More than 2000 customers have witnessed the development of Hirays, and more than 50 engineers are on call. 7 days fast delivery, is a commitment to you, but also to our own requirements. Choose Hirays, is to choose stability and high quality.