With the development of society and the improvement of people's living standards, the environment has also been greatly polluted. One of the biggest sources of air pollution is automobile exhaust. In order to control air pollution, people have invented new energy vehicles, and the distribution box of new energy vehicles is one of the most critical accessories of new energy vehicles. The quality of the distribution box of new energy vehicles determines the life and safety of new energy vehicles to a certain extent.

Product to be tested: automobile distribution box

However, the structures of power distribution boxes for new energy vehicles on the market are often the same with little difference, and the general waterproof performance is relatively poor. Therefore, in case of rainy weather or bad weather during daily use, it is very easy to cause damage to parts and reduce the service life of the power distribution box. Therefore, it is necessary to provide water detection methods for automotive distribution boxes.

Water detection fixture for automotive distribution box

According to the needs of customers, the automotive distribution box needs to reach the IP68 waterproof level. Hirays Technology uses the following equipment and solutions for it:

Equipment used: Hirays’ HC classic series air leak tester

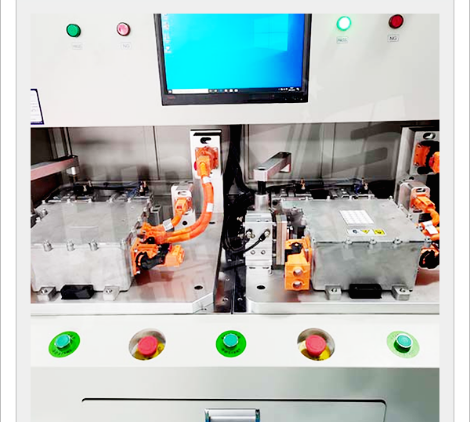

Solution: use direct test function, with test pressure is 40KPA, filling time is 30s, pressure stable time is 30s, test time is 30s, and the leak max is 0.05KPA .Test fixture is designed according to the structure of the distribution box. All holes and joints on the distribution box are blocked with the fixture, and double position cabinet tooling is customized according to the customer's requirements to meet the customer's requirements for testing two at the same time. The distribution box is placed in the fixture, and the connector is inserted to the designated position. After the plugging is completed, the instrument enters the test process. The air pressure inside the distribution box is monitored and detected through inflation, voltage stabilization, testing and other processes. The system automatically judges the products that cannot reach the test pressure or the measured leakage value exceeds the upper leakage limit as NG according to the set parameters.

Double station automotive distribution box air leak tester equipment

After the water detection, the automotive distribution box is more reliable in terms of waterproof effect. The use of Hirays HC classic series air leak tester is more efficient and accurate than traditional testing methods, and is more popular with automotive distribution box customers.

Double station automotive distribution box air leak test equipment

Hairuisi Automation Technology Co., Ltd., founded in 2008, is headquartered in Shenzhen, one of China's high-tech industrial cities. We are a modern high-tech air leak testing equipment technology enterprise integrating R&D, design, production, sales and after-sales service. Hairuisi Technology has been committed to the R&D and production of air leak testing automation equipment. For more than ten years, it has concentrated its ingenuity to forge high-end air leak testers.