Medical bottle leak test process – Hirays’ air leak tester

- Model: Medical bottle leak test process – Hirays’ air leak tester

- Category: Medical instruments

- details:

We shared a case about infusion tubes in the last article, today we will look at another common medical product - the case of bottles.

Bottles in the medical industry are mostly used as containers for potions or pills.

Sometimes it contains substances harmful to the environment and animals. If the bottle is not properly sealed, the liquid medicine or pill leaks out of the bottle, it will cause harm to the surrounding environment and human beings. Therefore, there is a high requirement for the air leakage of medical bottles.

Let's take a look at the following air leak test case of medical bottles.

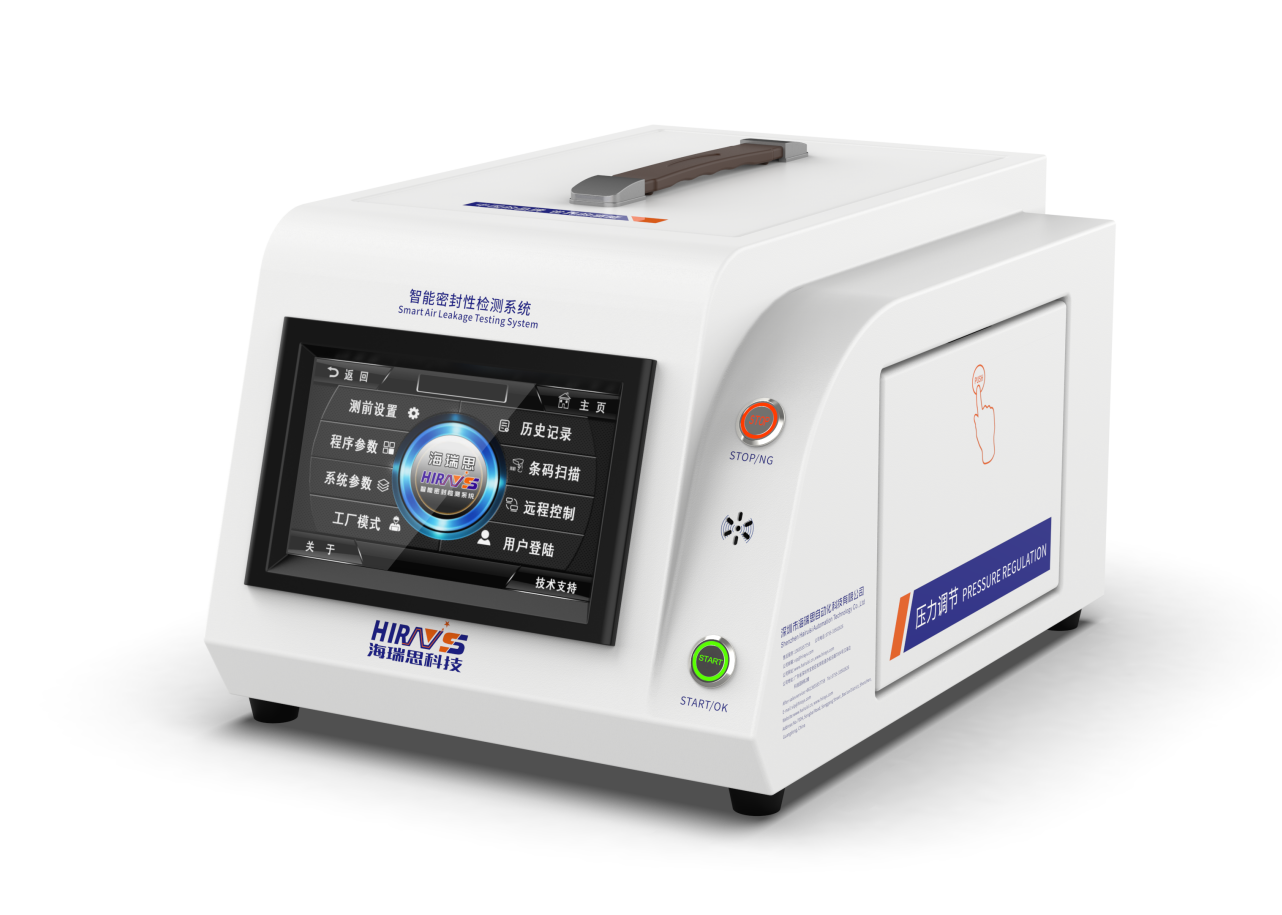

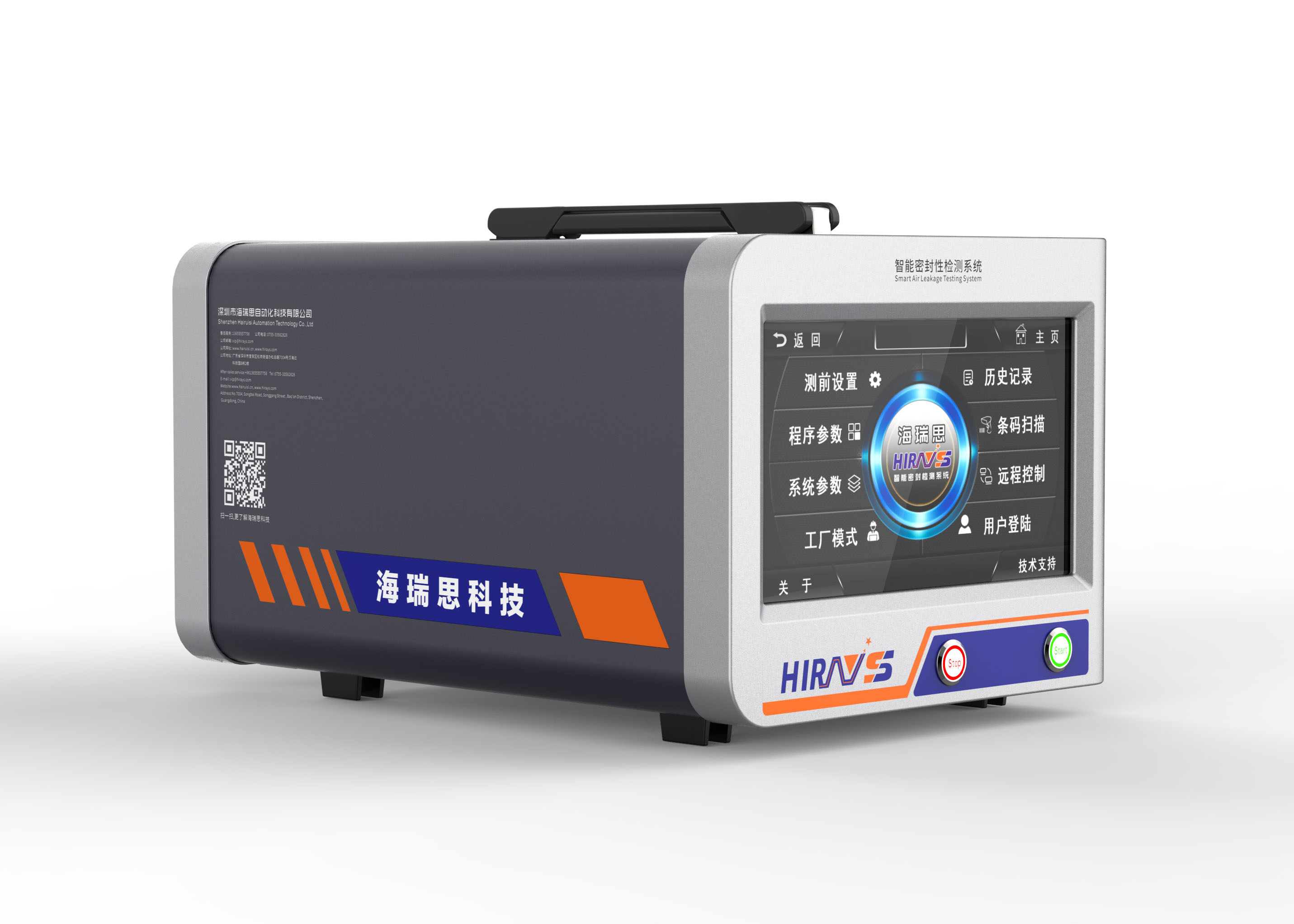

Testing equipment: HC classic series air leak tester

Test method: according to different types of bottles and customer needs, customize different jigs and toolings.

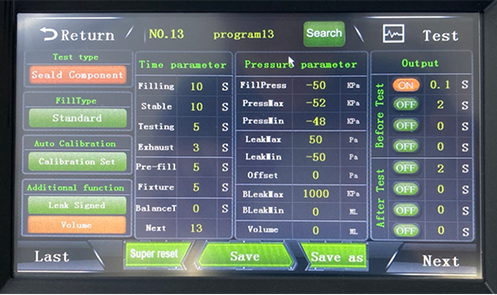

Use the test type of Seald component and volume, put the product to be tested into the mold, press the start key of the tooling, and start the test. Negative Fillpress pumping: - 50Kpa; Filling time: 10s; stable time: 10s; testing time: 5s; Pre-fill: 5s; Fixture time: 5s; LeakMax: 50pa. During the test, if the leak value exceeds the set value, it means that the product to be tested is defective, otherwise it is qualified.

Advantages of Hirays’ air leak tester machine:

l High precision mold processing , up to 0.02mm;

l Air leak tester, resolution up to 0.1PA;

l Hirays has all product lines of air leak tester, real water detection tester and HE leak tester, which can meet the use scenarios of all leak testing from trial production to mass production;

l Hirays has the ability of rapid system integration, and can deliver goods within 7 days as soon as possible after placing an order;

l The designed testing system strictly considers the stability and accuracy of the test results;

Profit of Hirays’ air leak tester machine:

l High precision, ensuring the stability of the mold;

l High resolution, even the smallest leakage can be accurately detected ;

l All the requirements of air leak testing can be packaged and purchased in Hirays to reduce the total cost of ownership;

l Quick response, when the internal process is completed, the test equipment is just finished;

l Strict requirements, bring a stable testing system to help you select defective products ;