Share the parameters of the air leak test of the infusion tube

- Model: Share the parameters of the air leak test of the infusion tube

- Category: Medical instruments

- details:

The infusion tube is one of the medical equipment that we often see in our lives. It is called disposable intravenous infusion device in medicine. It is aseptic and can establish a channel between the vein and the liquid medicine for intravenous infusion.

The disposable infusion set is generally composed of eight parts, including intravenous needle or injection needle, needle cap, infusion hose, liquid medicine filter, flow regulator, drip pot, bottle stopper puncture device, air filter, etc. Some infusion sets also have injection parts, dosing ports and so on.

Its working principle is that under the action of atmospheric pressure, the liquid in the bottle flows into the drip bucket along the thin infusion hose. When the water column pressure of the drip bucket is greater than the venous pressure, the liquid in the bottle flows into the vein along the hose.

In order to avoid the air in the infusion tube is not completely discharged, or the connection of the catheter is not tight, which causes the air to enter the vein, thus leading to the abnormal discomfort of the lung and chest of the infusion patient, so before the infusion tube is produced and left the factory, the manufacturer must do the process of air leak detection of the disposable infusion tube.

Today, we share the air leak test parameters of disposable intravenous infusion tubes.

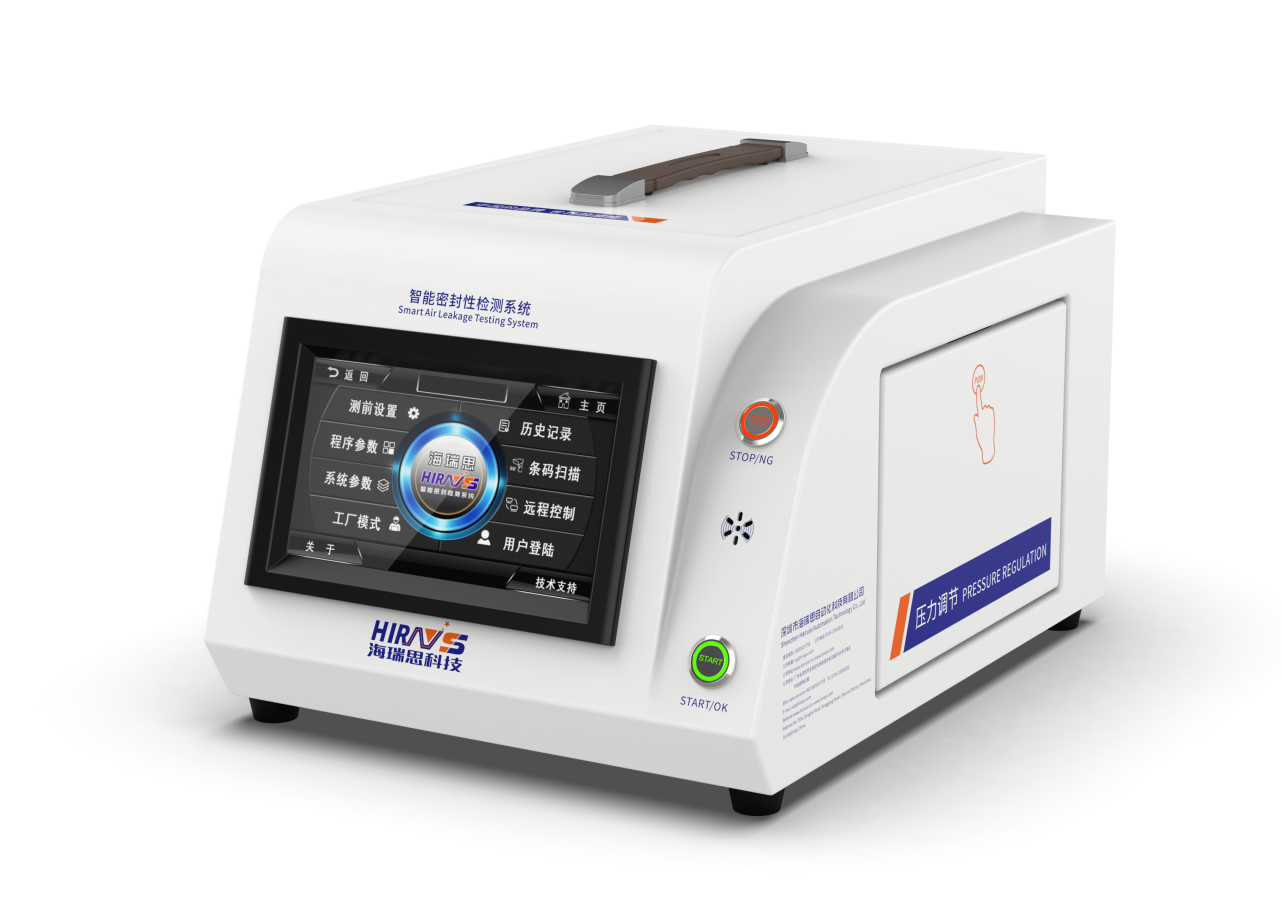

Testing equipment: HC classic series air leak tester machine (flow type)

Solution: According to the structure of the infusion tube and customer needs, select the Luer connector and adhesive to connect the infusion tube and the tester's air tube.

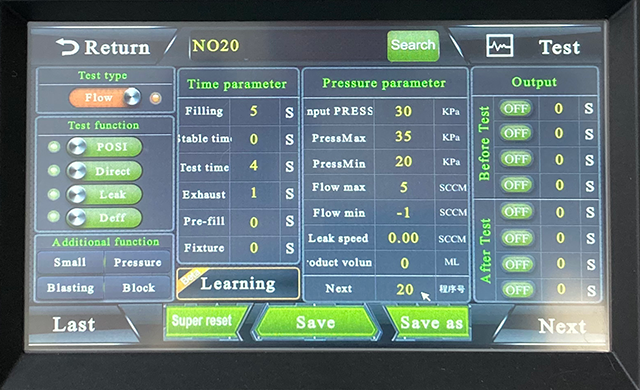

Use the flow test type to connect the infusion tube to the tester. After pressing the start button, the tester will enter the test program. The Input press is 30Kpa, the filling time is 5s, and the testing time is 4s.

If the leak value exceeds 5L/min during the test, it indicates that the product to be tested is unqualified and is a defective product; If it is not exceeded, it is qualified.

Advantages of Hirays’ air leak tester machine:

l High precision mold processing , up to 0.02mm;

l Air leak tester, resolution up to 0.1PA;

l Hirays has all product lines of air leak tester, real water leak tester and HE leak tester, which can meet the use scenarios of all leakage tests from trial production to mass production;

l Hirays has the ability of rapid system integration, and can deliver goods within 7 days as soon as possible after placing an order;

l The designed testing system strictly considers the stability and accuracy of the test results;