What factors should be paid attention to when choosing air leakage testing equipment and methods?

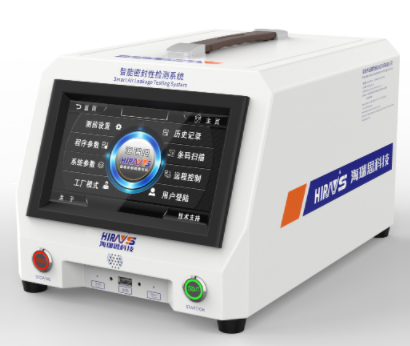

Nowadays, there are many kinds of air leak tester equipment and methods, and people are confused about the choice of them. As the industry leader in air leakage testing, Hirays tells you: the following factors should be considered when choosing the equipment.

1. Consistency

For some leak testing methods, no matter whether the inspector is skilled or not, the testing results are basically the same; Some methods are used by the expert and the uninitiated with completely different results. If possible, methods should be used that do not require skilled expertise to detect correctly. Each method has different technical keys, and different inspector may not be able to get consistent leak testing results.

2. Stability

Air leakage testing is a comprehensive technology of measurement and detection. If the data obtained from the test is unstable, it is meaningless. The right air leakage test requires not only the stability of the test instrument, but also of the test method itself.

3. Reliability

Failure to detect leakage does not mean that there is no leakage, which should be judged. When a certain method is used for leakage testing, it is necessary to know whether the method is reliable. The reliability of leak testing results is related to the consistency and stability of the methods described above.

4. Principle of leak testing

No matter which air leakage testing method is adopted, its basic principle must be understood. Its method involves a wide range of contents, and reflects a variety of measurement and testing techniques. It is not easy to have a detailed understanding of the principles of many testing methods. This book will briefly introduce the basic principles of common leak testing methods.

5. Response time

No matter what method is used, it will take time to detect the leakage rate. The length of the response time may affect the accuracy and sensitivity of the leak testing. In general, extending the testing time will improve the sensitivity, but if the time is too long, the testing accuracy may be reduced due to the change of environmental conditions. The response time includes the air leakage test instrument itself, the lag time of the gas flow, and the time required for various preparations. This must be taken into account when selecting a leak testing method.

6. Judgment of leakage point

Some leak testing methods can only judge whether there is leakage in the system, but cannot determine where the leakage point is. Some leak testing methods can determine the leakage point, but also determine the leakage rate. If it is only for the purpose of determining whether the device is qualified, the former method can be used. The latter method must be used when performing maintenance or to find out the cause of the leak, which sometimes also results in missed inspections.

This article comes from Hirays Automation: Hirays Automation (http://www.hirays.com), the pioneer of high-precision air leakage testing equipment, focusing on mobile phone waterproof testing, camera waterproof testing, IP waterproof level testing, wire waterproof testing , Speaker waterproof testing and other leakage testing equipment.