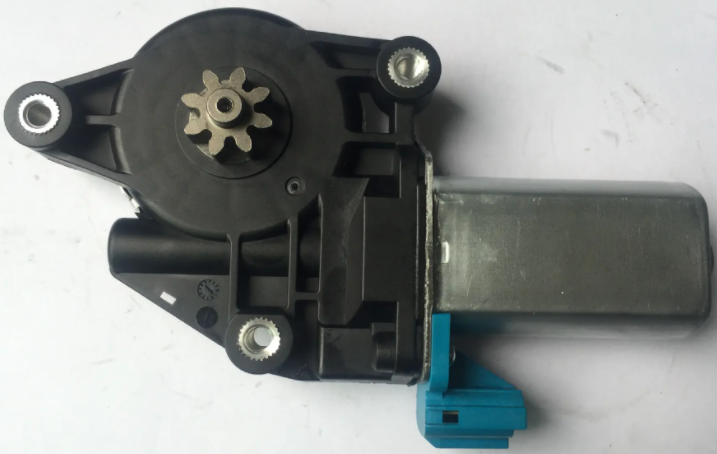

Glass lifter, also known as window shaker or lifter, uses the motor to rotate to drive the glass lifter to move the glass up and down along the slide, so as to achieve the lifting of the glass, mainly to reduce the air resistance of the car, and has the functions of shielding, sealing, heat insulation and sound insulation, but also an important part of the overall shape of the car.

The electric glass lifter for vehicles is composed of motor, reducer, guide rope, guide plate, glass mounting bracket, etc. The automotive lifting glass is mainly driven by the motor, in order to ensure driving comfort and driving safety, the motor needs to have good air tightness.

Today, we are sharing a case of air leak test for automotive glass lift motor.

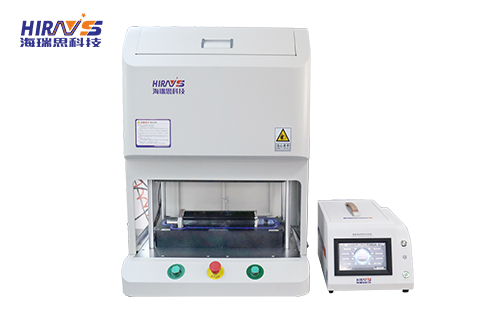

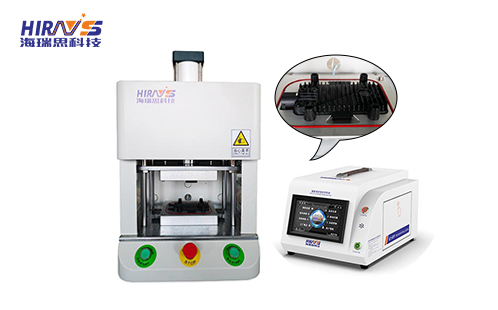

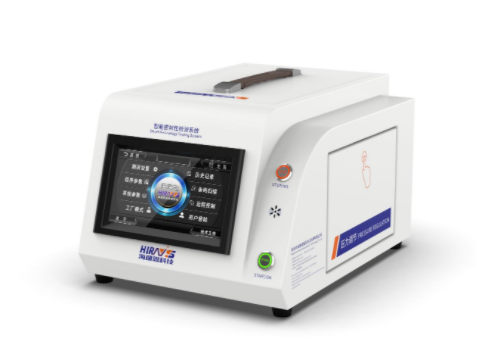

Testing equipment: HC classic series air leak tester.

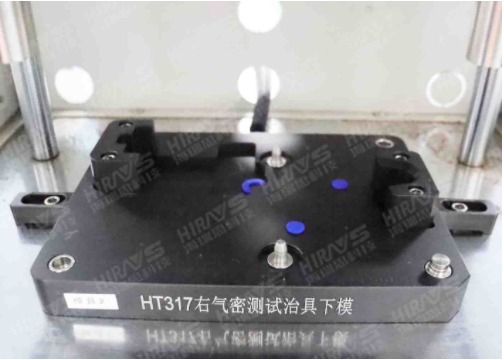

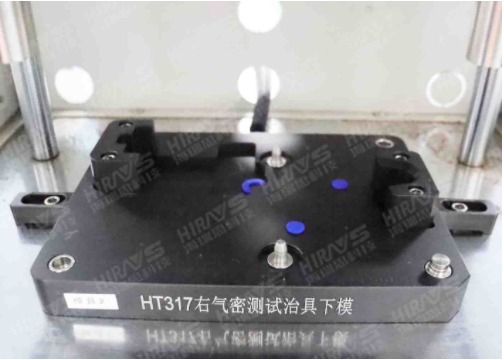

According to the product shape, structure and customer needs, customize the corresponding fixture and tooling.

Use the direct test function, select the set program, press the start button, and the instrument starts detection. The Input press is 20Kpa, the filling time is 5s, the stable time is 5s, the test time is 5s, and the Exhaust time is 2s. If the leak value does not exceed 30pa during the test, it means that the tested product is qualified, otherwise it is defective.

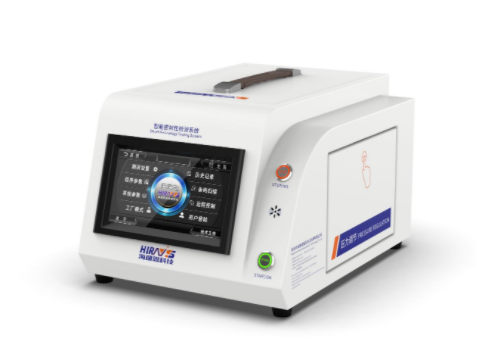

Hirays’ air leak tester

● High precision

The powerful 32-bit processor and 24 bit A/D converter, together with the patented "intelligent differential pressure" algorithm, have the same test accuracy as the differential pressure type. Compared with the differential pressure type, the testable leakage range is larger and basically equal to the test range.

● AI algorithm

The automatic learning function, according to the characteristic information of the sample to be tested, analyze the effective data of the sample information, automatically judge and identify the critical point of leakage, and obtain better process time parameters through the analysis of the critical value, which greatly improves the difficulty of initial contact with the instrument.

● Powerful testing function

The system comes with 2 pressure forms, 8 basic determination methods, can be combined into more than 20 kinds of test functions, easily cope with a variety of conditions, to meet your various requirements!

● Stable, reliable and efficient

Built-in self-developed patented technology, "IVT" pneumatic seal valve island; greatly improve the test accuracy, speed up the inflation speed, and at the same time the large leak has been detected in the inflation stage, saving the entire test time.

● Simple testing process, more universal

No need for standard parts, no need to do two sets of fixture, no need to compare with standard parts, exclude the deformation error after multiple tests of standard parts.

● More expandable

Modular design, according to the requirements to realize a host control multi-way full-function valve terminal composed of an execution module. Realize full-featured multi-channel testing including positive and negative pressure and indirect testing.